- Contact Us

- phone: +49 (0) 931 32298-0

- mail: info@innowep.com

- Friedrich-Bergius-Ring, 11

- 97076 | Würzburg | Germany

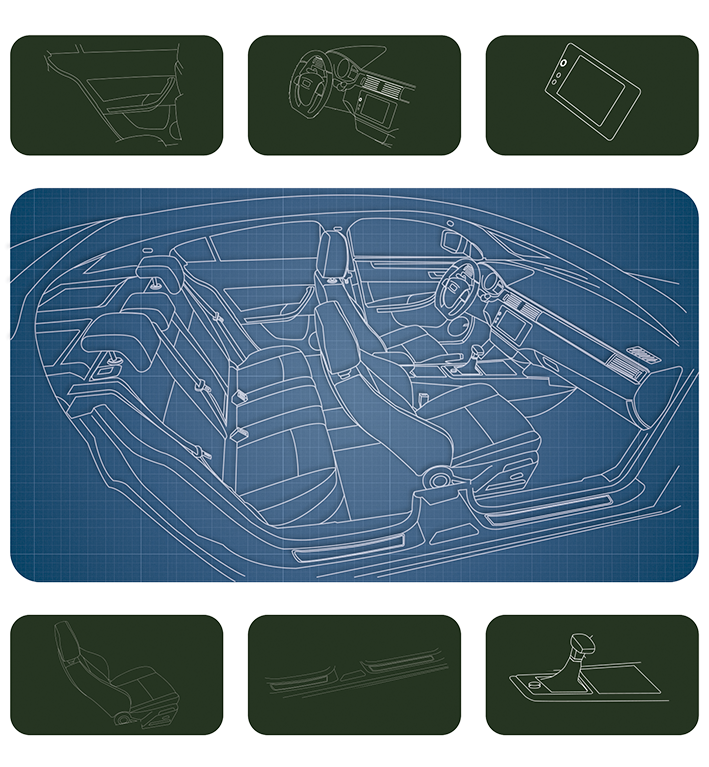

Quality control of materials used in the manufacture of a car is essential to ensure that the car is safe and reliable. This involves testing the materials used to ensure they meet the required standards for the application. The tests used to evaluate the materials often include physical tests such as tensile strength, hardness, fatigue, and wear testing as well as chemical tests such as corrosion resistance and flammability testing. Manufacturers also use non-destructive testing such as ultrasonic and radiographic testing to ensure the materials meet the required specifications. Additionally, manufacturers conduct visual inspections of the components and materials to ensure they meet the required standards.

Interior car materials can be tested for various characteristics such as durability, wearability, colorfastness, stain resistance, and fire resistance. Durability tests can involve exposing the material to extreme temperatures, exposure to sunlight and other environmental elements, and abrasion tests to determine how much wear and tear it can handle. Tests for wearability can be conducted by simulating everyday use and abuse, such as with a mechanical abrasion machine. Colorfastness tests involve exposing the material to light and other chemicals to determine how colorfast it is. Stain resistance tests involve applying various substances to the material and then testing to see how easily it can be cleaned. Fire resistance tests involve exposing the material to a flame or other high temperature source to see how it performs.

To test the touchscreen hand and fingertip abrasion inside of cars, a series of tests can be conducted. These tests could include a combination of physical and visual inspections, as well as tests to measure the touchscreen's durability. Physical tests could include a scratch test, in which a weighted finger or stylus is used to press against the touchscreen to measure its resistance to abrasion. Visual inspections could include a close examination of the touchscreen for signs of wear and tear, as well as an assessment of the touchscreen's sensitivity to pressure. Additionally, the touchscreen's responsiveness to various inputs could be tested, to measure its accuracy and consistency.

We offer tests in accordance with many standards or specifications including:

• AATCC

• Audi

• Daimler

• GB/T

• JIS

• ASD-STAN

• BMW

• DIN

• IEC

• PSA

• ASTM

• BS

• Ford

• ISO

• VW

Questions?

We are happy to help!

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany