- Contact Us

- phone: +49 (0) 931 32298-0

- mail: info@innowep.com

- Friedrich-Bergius-Ring, 11

- 97076 | Würzburg | Germany

The most complete line of equipment for fingertip and hand abrasion testing. More than 30

years of experience alongside the largest OEMs in the world. Get access to the most

realistic simulation of human touch abrasion.

The only open multi-modular system that provides a complete mechanical testing solution for

the evaluation of bulk materials and surface coatings. The best to the R&D center of our

industrial partners and research institutes all over the world.

Severe abrasion occurs during a fast and high dynamic motion. Dyna-SPA®, is the only

machine which combines all kinds of scratch and abrasion tests within one machine with

freely programmable speed and stroke.

TRACEiT® is by far the fastest mobile optical profiler. The real-time measurement of 3D

topography as well as the documentation of visual impression makes it widely used in

QC/QA, design and research departments.

An ample range of bearing tests can be performed with our line of Test Rigs. From standard

to customized, meeting the needs of different industries and counting on support and training

worldwide.

Full control of lubricant lifespan and functionality can be achieved through our range of test

rigs. Different scenarios and environments, from standard to customized, with support and

training on all continents.

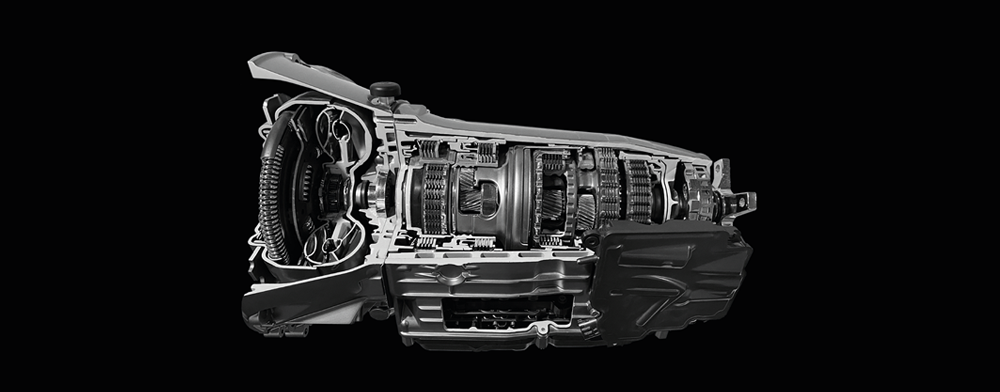

Gears need complete control to ensure the required performance in different engines and

different industries. The solution to your problem is in our line of Test Rigs for Gears. Full

support and training. All around the world.

Full spectrum of tests for clutches considering different torques, loads, speeds and

temperatures. Discover our gear testing equipment. Support and training, wherever you are.

Fingertip and Hand Abrasion

From product conception, quality, usability, functionality and the satisfaction generated are the main values that guide the development team. Ensuring that the materials used are under control and allow the product to achieve these values is our concern. Simulating human handling in a precise, continuous and controlled way has been our challenge for over 30 years. Our equipment allows the industry to have, from the initial concept of the product to its production line, total control over Quality, Durability and Haptic.

Haptic

Haptics refers to using tactile feedback to enhance the user experience. When touching a product, the human brain will immediately decode that feeling into values about what it touches. Values such as roughness, structure, smoothness, adhesion... will imprint a concept regarding this product. How to scientifically define how human touch interprets your product? Innowep has the answer to that question.

Bearings, Gears, Lubricants and Materials under control

Bearings, gears and lubricants have been widely used in several industry sectors as automotive, aerospace, specialty steels, rail, wind energy, etc. To keep up with the speed of development of these industries, tests on these components must be constant and always expanding.

Different speeds, temperatures, loads and lubricants are used in different types of engines and Innowep follows every step of these industries. We supply equipment, consultancy, and training worldwide. A modern line of Test Rigs, with proprietary software and German manufacturing are available, including customized versions according to the needs of each client.

More than 30 years of experience shared with Partners

In this long journey, Innowep has been supplying its partners with the very best in equipment, services and technical support. Since 1990, the Innowep team has followed all the steps of its partners' industries and keeps up to date in order to provide the best and most modern tests that guarantee better quality, durability and haptic in product surfaces. Years and years of experience with data from the most varied scenarios, make Innowep an essential partner for any company that wants to keep its products under control.

Product Line

Innowep GmbH

We are Innowep.

From hand abrasion & finger abrasion tester to complete material component friction and

fatigue test bench.

We’re innovators, haptic study pioneers, developers, research partners but, above all, in our

hearts, we are engineers.

With a distinct focus on quality machines for materials and functional testings and the driving

force of innovation.

With new testing machines, we will always find the most suitable solution for you.

With our great design and performance made in Germany.

We have been innovating every day.

Because that’s what we stand for.

And have been standing for 30 years.

Questions?

We are happy to help!

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany