Precision in mechanics & lubricants testing.

Precision in mechanics & lubricants testing.

Innowep delivers cutting-edge solutions for bearing, gear, lubricant & synchronizer testing, trusted by OEMs and research institutes worldwide. Our modular rigs help you master durability, performance, and efficiency across drivetrain and tribology applications.

Mechanical Testing – Engineered for Reliability.

Company Profile

For over 30 years, INNOWEP has been a trusted partner in the development and testing of mechanical systems. Our expertise in tribology, friction, wear and material behavior has made us a leader in gear, bearing and lubricant evaluation across the global industry.

From electric drivetrains to industrial actuators, INNOWEP’s mechanical testing solutions are designed to simulate real-world stress conditions with the highest precision. We support engineers and researchers in developing components that meet today’s demands for performance, efficiency and longevity.

With cutting-edge instrumentation, software, support and calibration services, INNOWEP delivers measurable reliability – wherever mechanical systems move the world.

Global precision in motion-critical sectors.

Industries We Work With

Our tribology and mechanics testing systems are used wherever components are subjected to load, stress and motion – across a wide range of industries:

Advanced Bearing Testing. Modular. Versatile. Proven.

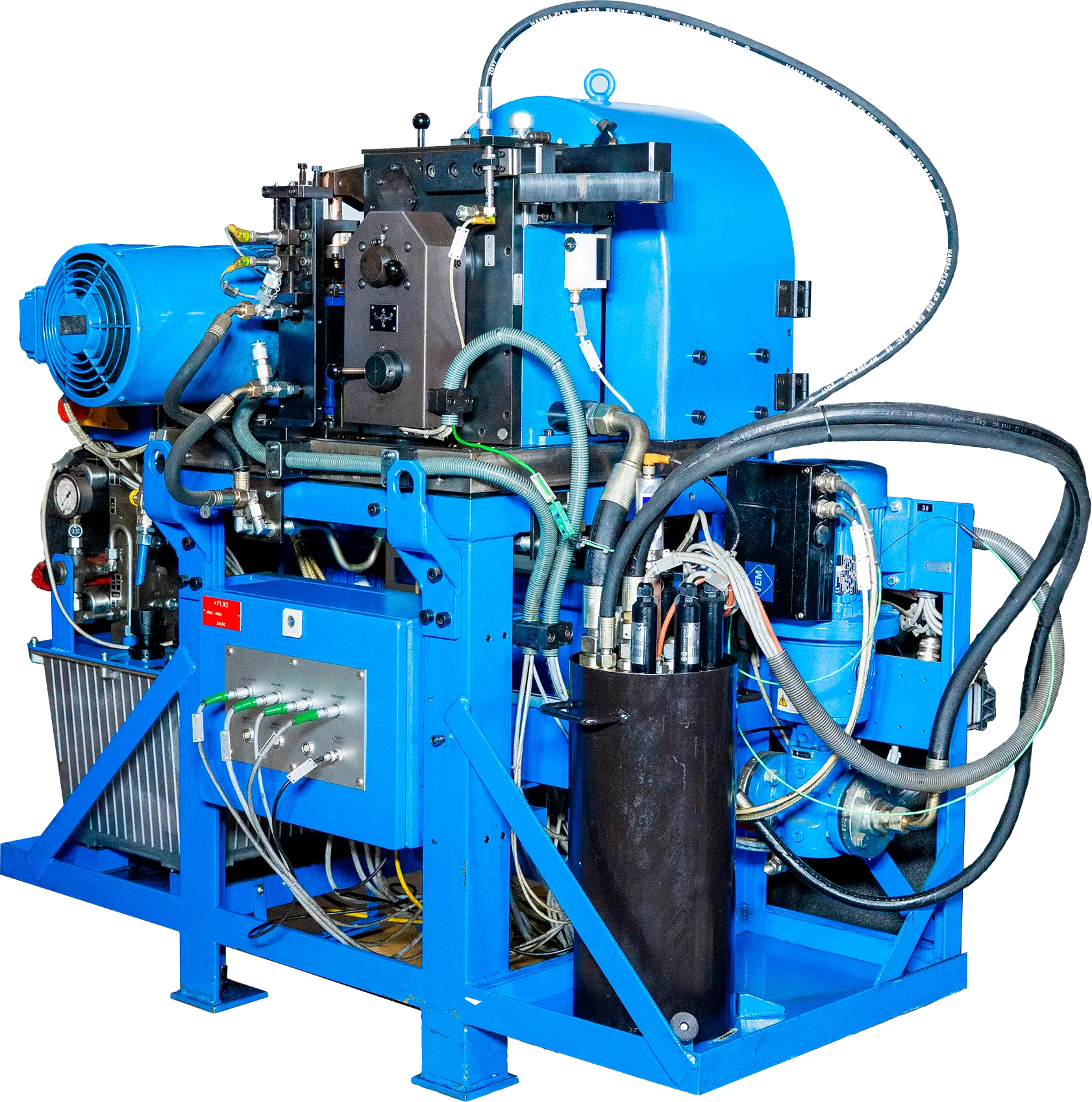

FARAX®-Bearing Lineup

INNOWEP’s FARAX®-Bearing series delivers a modular, high-performance platform for comprehensive bearing and lubricant evaluation — from standardized tests like DIN 51819 & DIN 51821 to fully customized fatigue and E-Mobility simulations. Designed for precision, flexibility, and reliability, each rig supports multiple load types, lubrication methods, and measurement systems — serving both industrial R&D and quality assurance across diverse applications.

Advanced Gear Testing. Modular. Reliable. Proven.

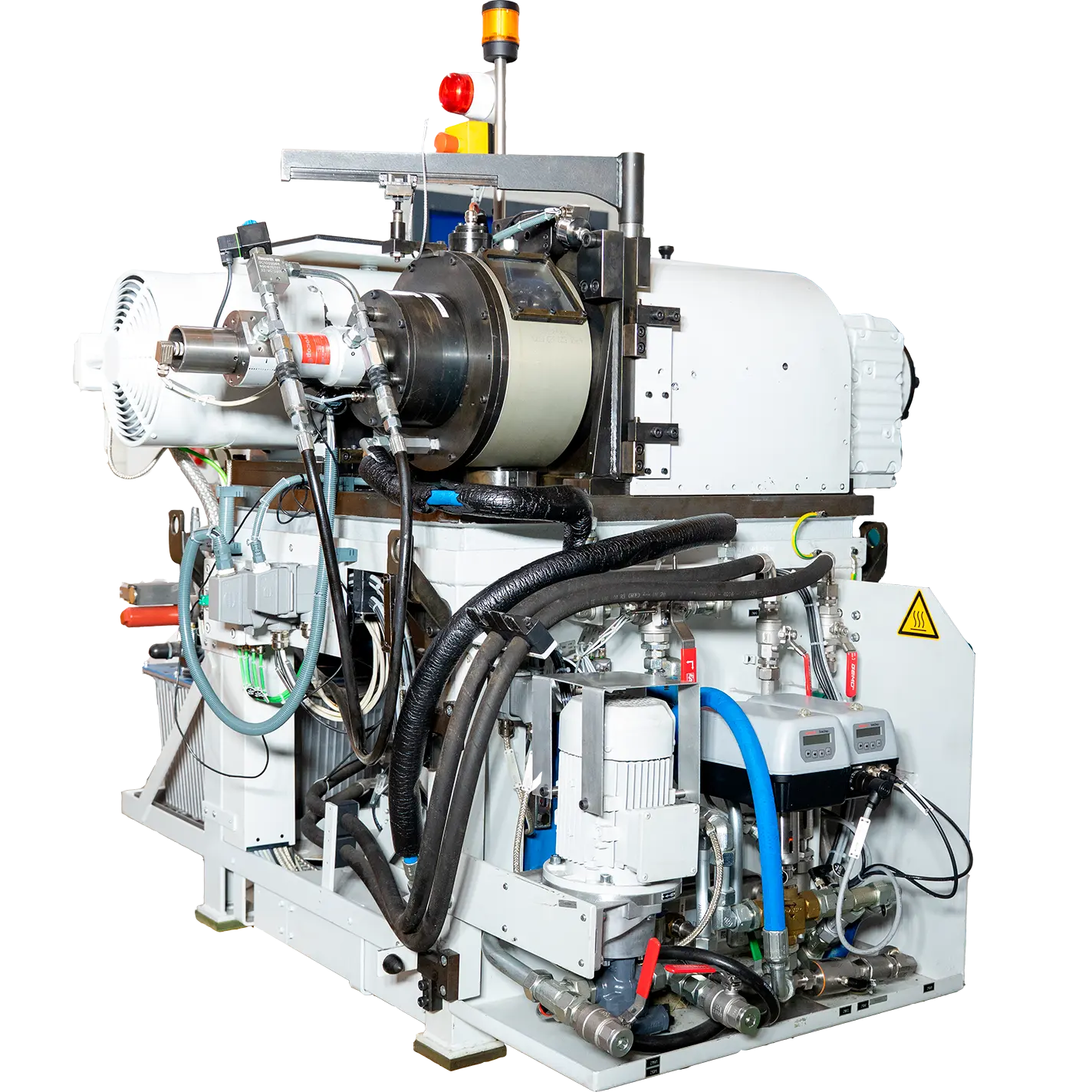

FARAX®-Gear Lineup

INNOWEP’s FARAX®-Gear series offers a flexible, high-precision platform for gear and lubricant testing — from mechanical and hydraulic load to high-speed and system-level configurations. Built for both traditional powertrains and E-Mobility systems, each rig is modular, fully instrumented, and compliant with key standards like ISO 14635, ASTM D5182 and FVA guidelines.

FARAX®-Gear-MU

Mechanical loading via weights or ratchet. Ideal for standard gear fatigue and lubricant tests.

Synchronizer Testing. Standardized. Industry-Proven. Evolving.

ZF/FZG Oil and Grease Testing

INNOWEP’s ZF/FZG-based synchronizer test rigs — FARAX®-SSP180 and FARAX®-KLP260 — offer established, standard-compliant platforms for investigating friction, wear, durability, and performance of synchronizer systems and multi-disk clutches. Developed in collaboration with leading transmission research centers, these rigs provide reproducible results under realistic load conditions — trusted by OEMs and Tier 1 suppliers across both conventional and electrified drivetrains.

SSP180

Synchronizer test rig (FZG-based) for analyzing friction behavior, wear, and service life of synchronizer rings.

KLP260

Test rig for evaluating force-travel characteristics and shift performance of synchronizer systems under realistic load conditions.

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.