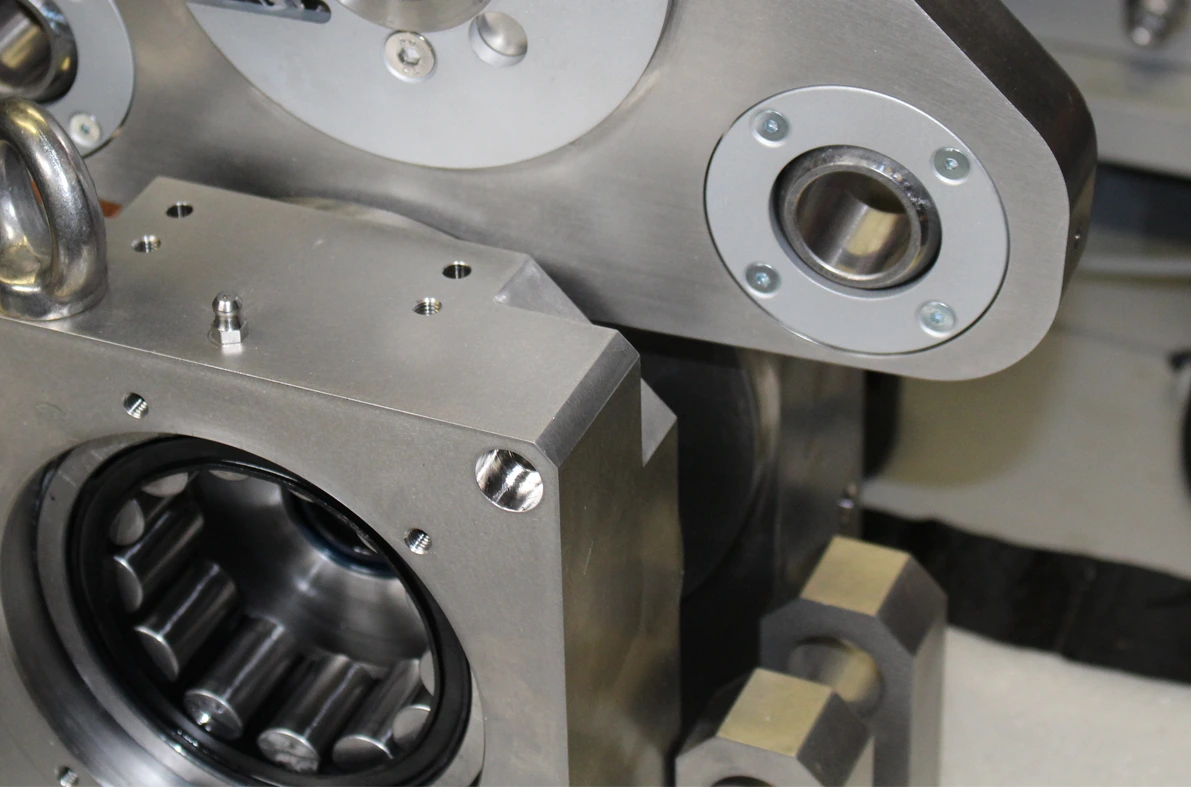

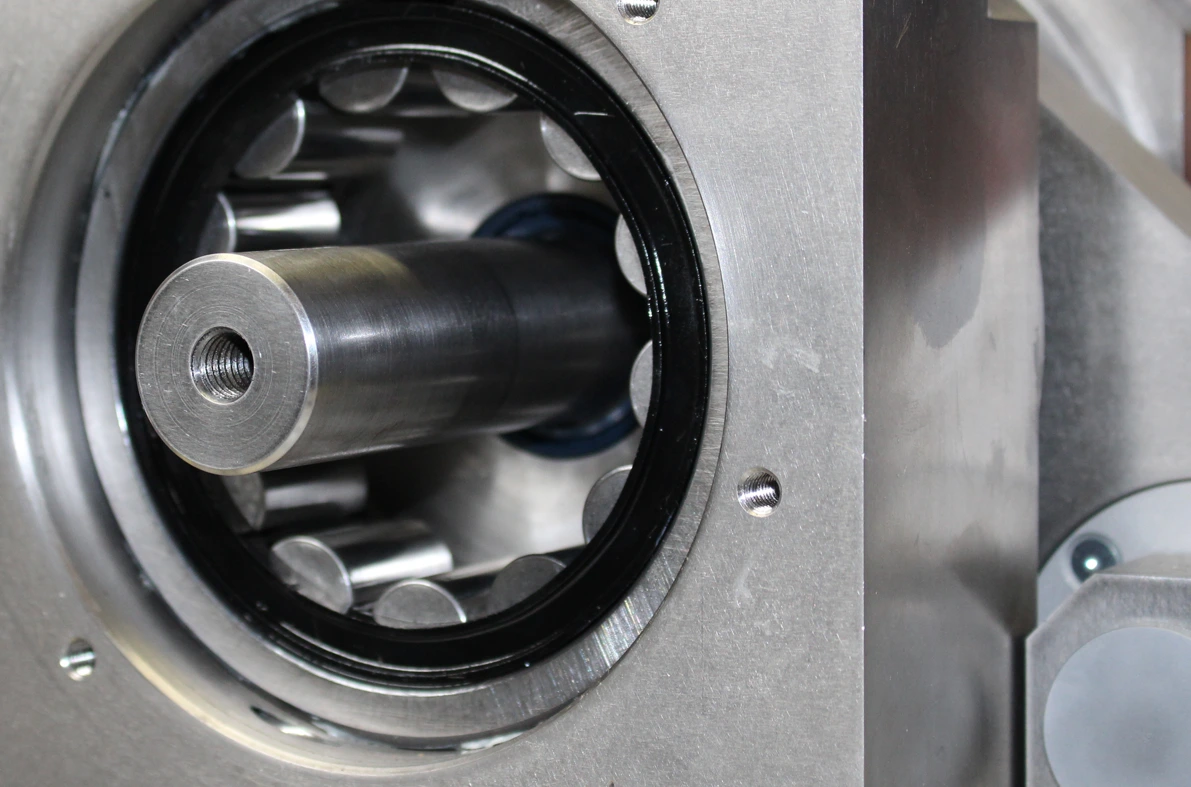

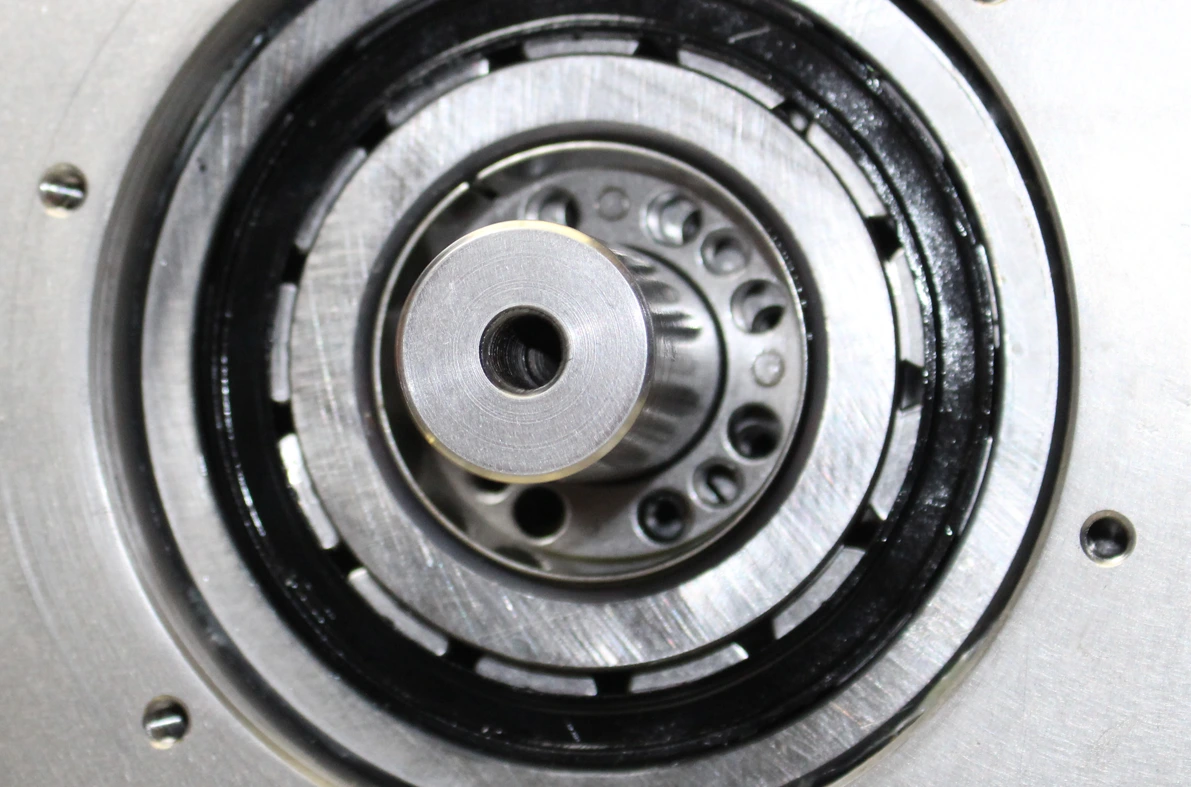

The FARAX®-E is an advanced fatigue and friction test rig specifically engineered for the demanding needs of E-Mobility. In an era where electric motors are replacing fossil fuel engines across all forms of transportation—cars, buses, boats, scooters, motorcycles, bicycles, and even aircraft—components such as gears, bearings, coatings, and lubricants must withstand high rotational speeds, variable loads, and challenging thermal environments.

To support this evolution, FARAX®-E enables precise evaluation of friction, wear, and fatigue life of components used in electric drive units and auxiliary systems.

Purpose & Application

Friction, wear, and fatigue behaviour of materials and coatings—combined with the right lubrication—are critical for quality, reliability, and performance of modern e-mobility products. The accelerated development cycles in this sector demand fast and reproducible testing.

The FARAX®-E fatigue test rig allows comprehensive testing of:

under high-speed, multi-load, and real-world operating conditions.

Features & System Highlights

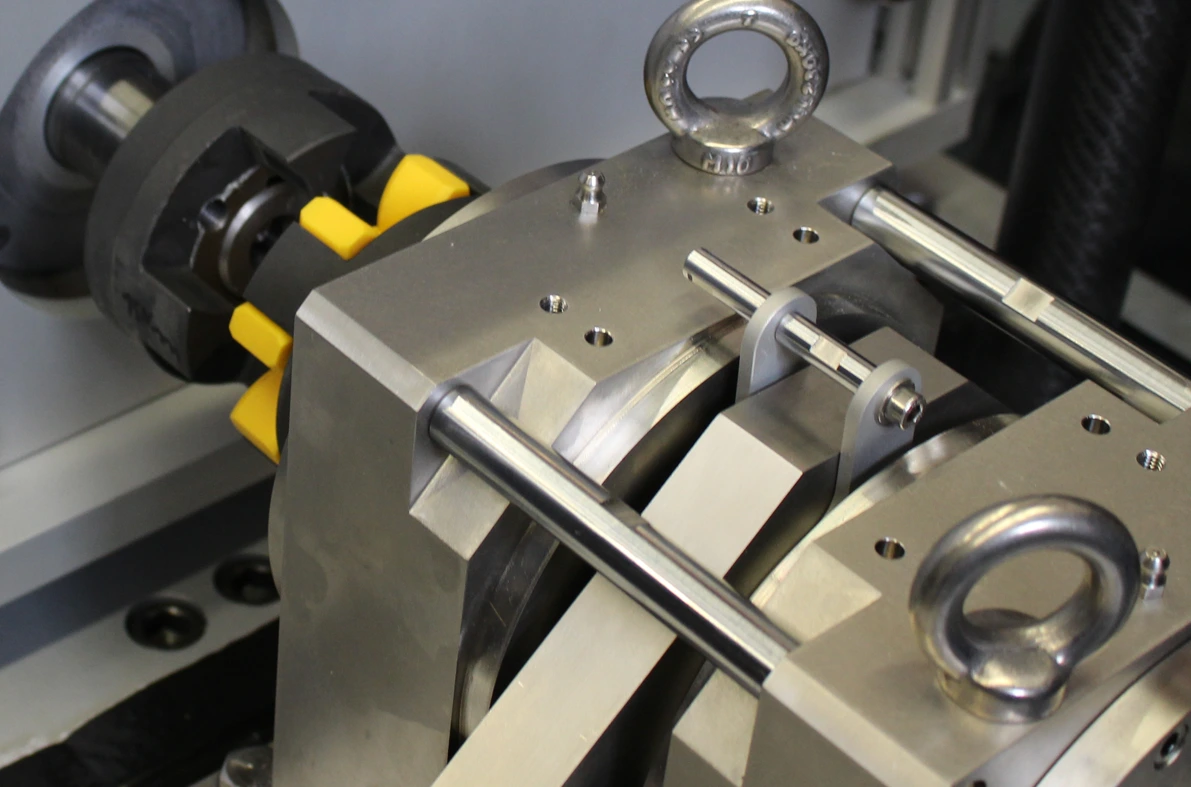

Designed as a modular system, FARAX®-E offers unmatched flexibility:

– Drive motor: adjustable up to 30,000 rpm

– Hydraulic loading system: enables simultaneous axial and radial loading, up to 100 kN

– Measurement system: real-time data acquisition for torque, temperature, vibration and more

In addition to its robust core architecture, the rig supports customizable configurations to match customer-specific components and test cycles. A wide range of bearings, materials, coatings, and lubricants can be evaluated for e-mobility applications.

Typical Test Scenarios

Components are tested under dynamic loads and high rotational speeds, simulating realistic driving conditions. Bearings, gears, and lubricants are exposed to varying torque, temperature cycles, and vibration patterns. This enables manufacturers to:

Technical Specifications

| Parameter | Value |

|---|---|

| Max. Test Speed | up to 30,000 rpm |

| Loading | Hydraulic, simultaneous axial & radial |

| Max. Load | up to 100 kN |

| Measurement Parameters | Torque, Temperature, Vibration, Speed |

| Lubrication Options | Grease, oil circulation, spray, drip |

Innowep’s FARAX®-E is part of a complete line of tribology test rigs supporting the quality assurance and product development of electric drive technologies. Designed for both R&D labs and manufacturing environments, it ensures optimal component reliability from concept to production.

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.