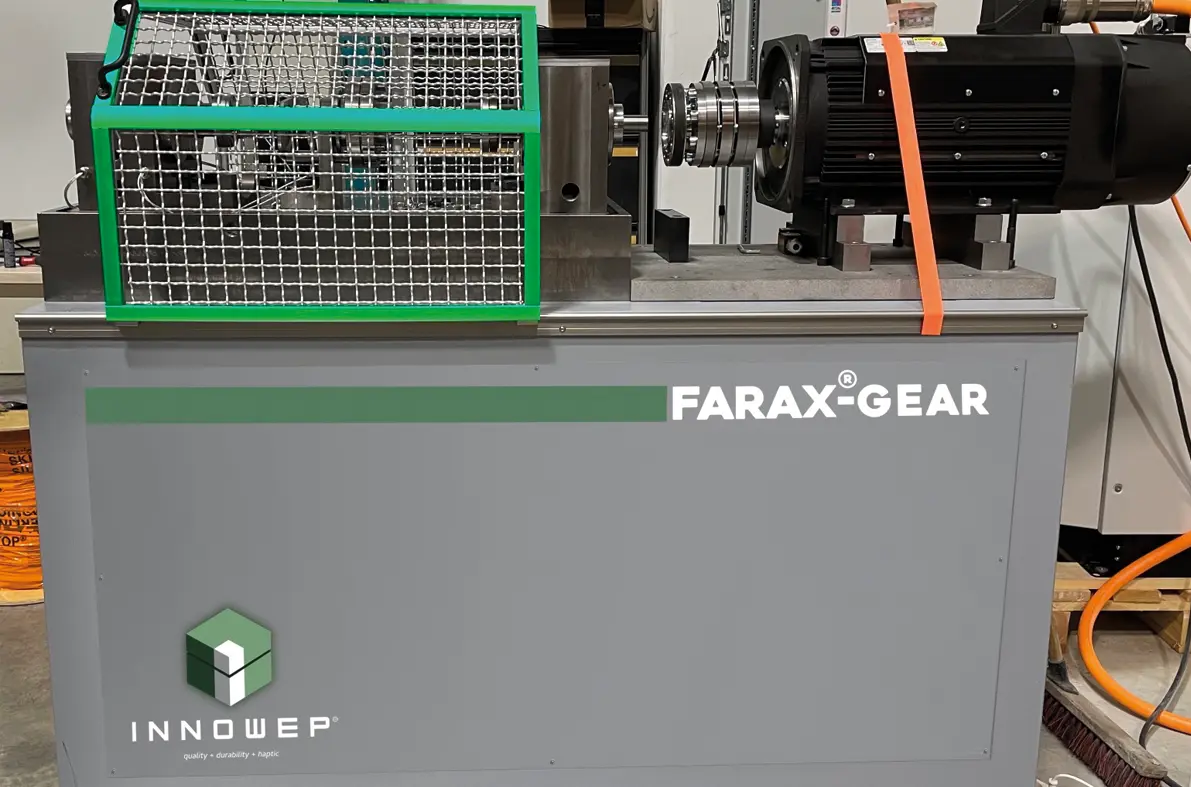

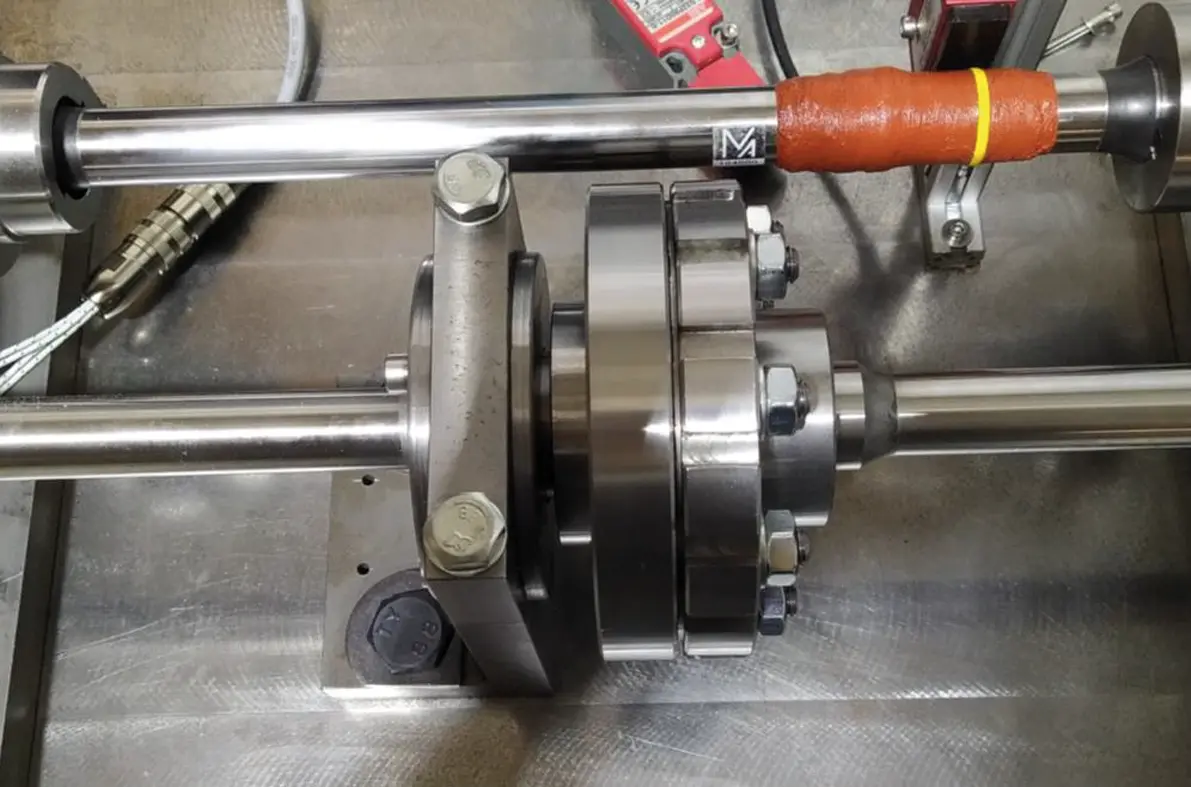

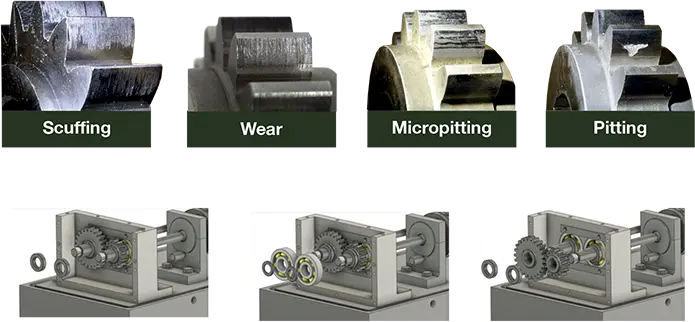

The FARAX®-Gear-HS – also known as the „Ryder Gear Rig“ – is specifically designed for high-speed, high-temperature testing of gear scoring and scuffing. It is the go-to system for pushing gear materials, surface treatments, and lubricants to their limits under real-world e-mobility and high-performance conditions. With dynamic loading, precise thermal control and advanced monitoring, the HS model is ideal for performance benchmarking and critical design validation.

Applications and Test Types

FARAX®-Gear-H is ideal for:

Test Focus:

High-speed surface interaction, rapid wear scenarios, thermal degradation behavior.

Technical Specifications

| Parameter | Value |

|---|---|

| Speed range | Up to 10,000 rpm or higher |

| Temperature | Up to 120 °C |

| Torque | Mechanical and/or hydraulic load |

| Test standard | FED-STD-791D (Ryder Gear Scuffing Test) |

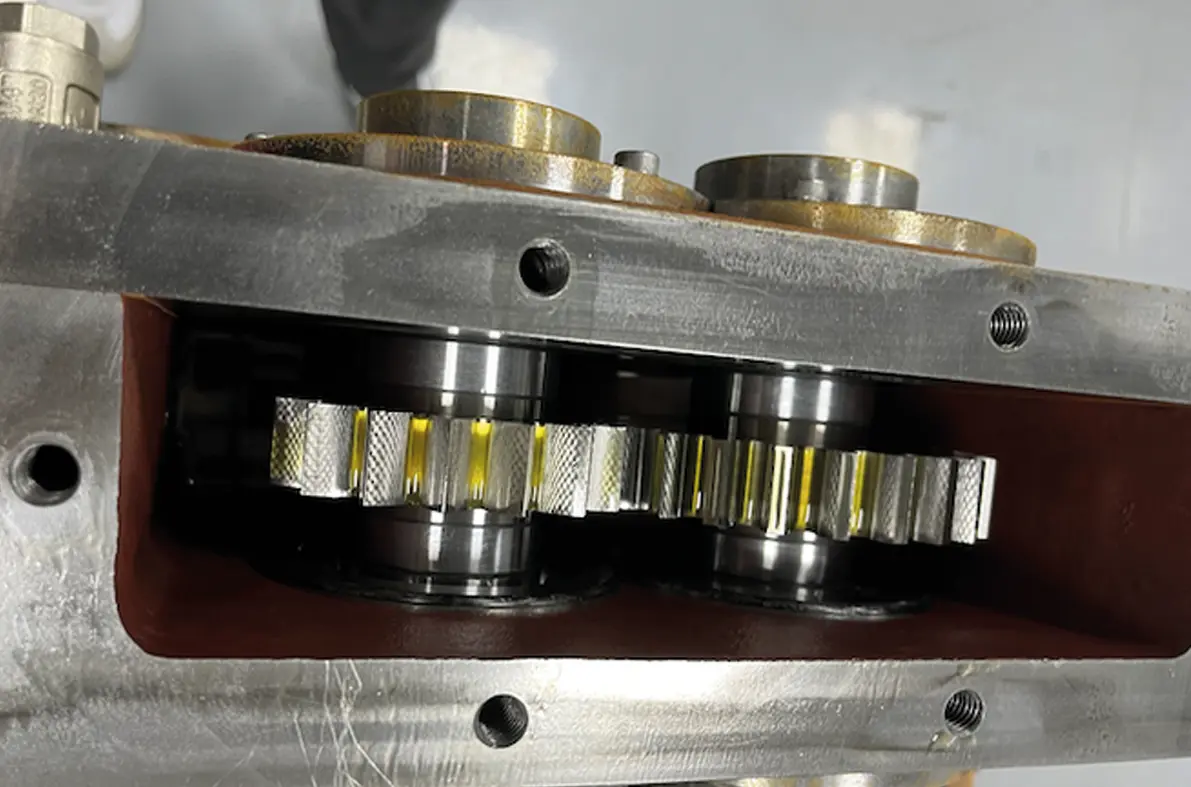

| Gear compatibility | Standard ZF test gears (A10, A20, C types, Ryder) |

| Lubrication | Immersion and oil injection lubrication |

| Axis distance | 91.5 mm |

| Drive system | Direct drive, with automated load spectrum and torque measurement |

Note: As a specialized configuration, the HS model can be adapted to meet client-specific high-speed or endurance test protocols. Please contact Innowep for project-based configurations.

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.