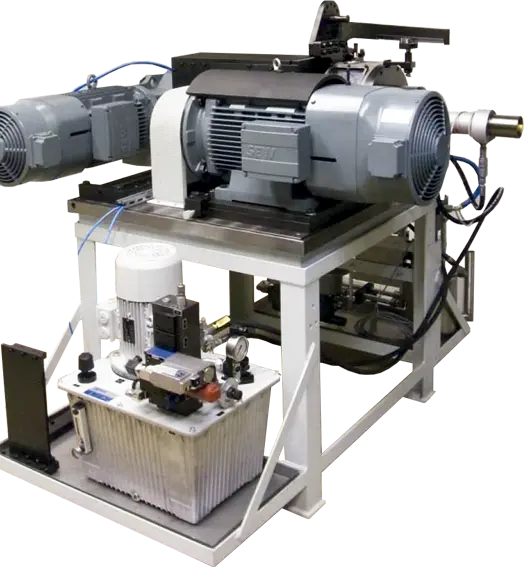

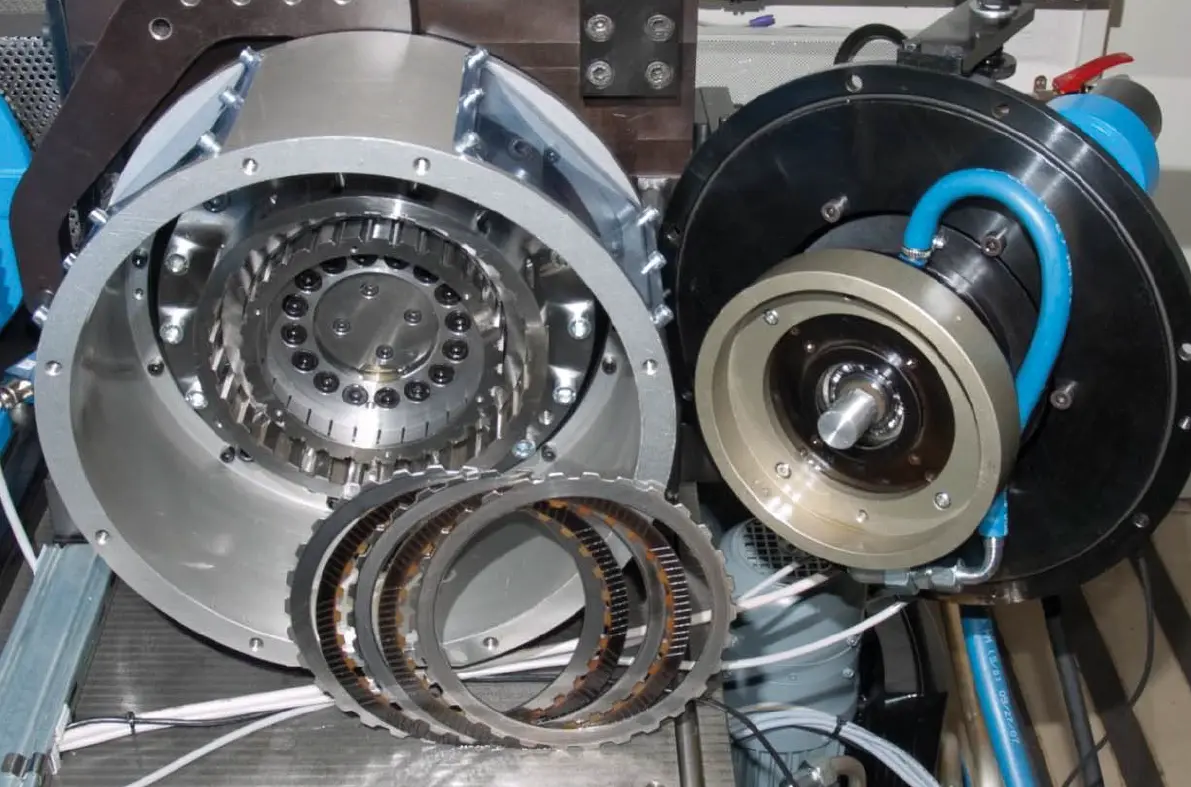

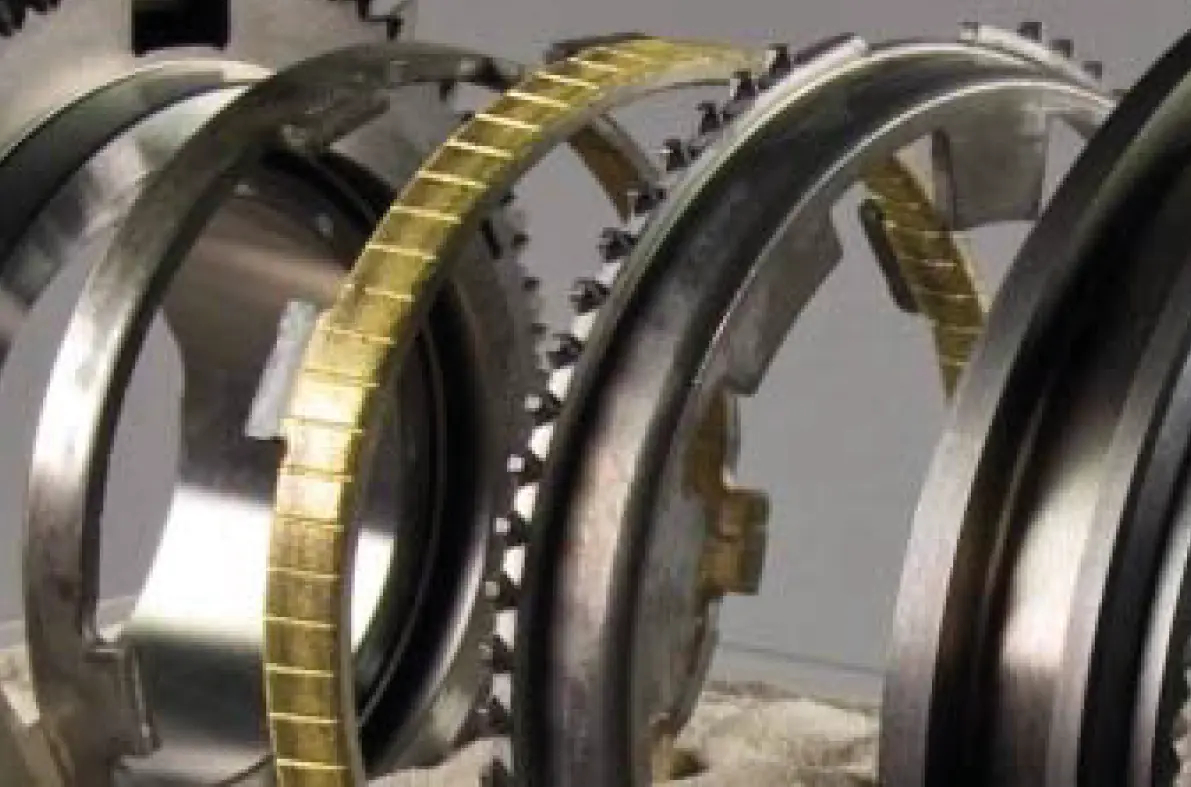

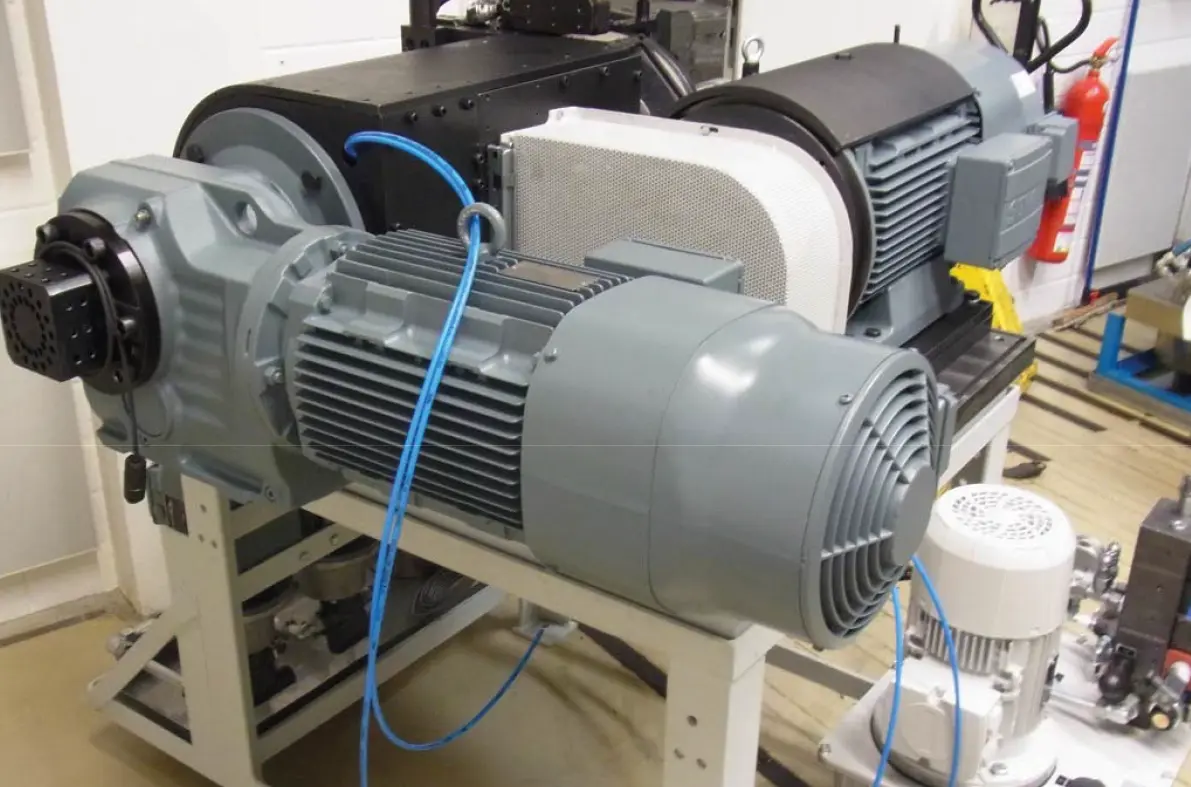

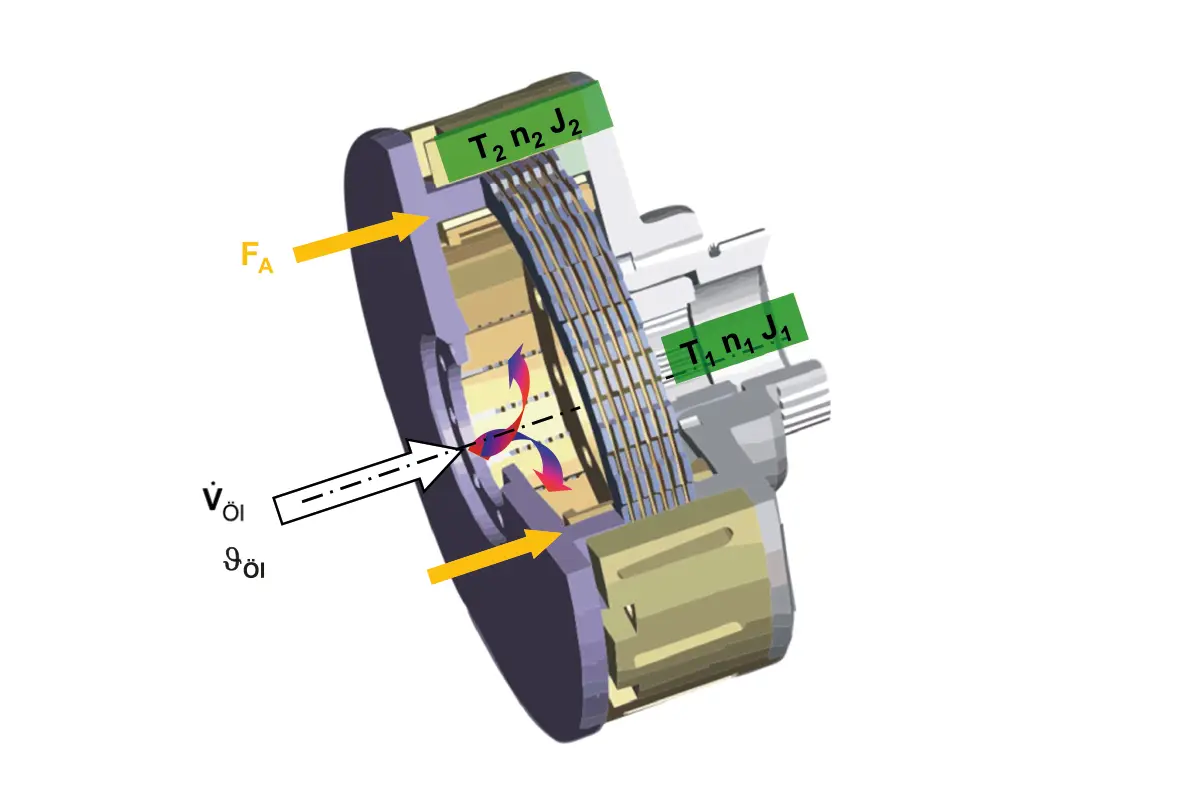

The FARAX®-KLP260 is a standardized test rig developed for testing wet multi-disc clutches under realistic conditions. Designed with heavy-duty synchronizers and industrial-grade transmission systems in mind, it enables detailed evaluation of friction behavior, endurance, wear, and thermal characteristics. Through direct torque measurement and flexible control parameters, the rig supports both R&D and quality assurance use cases.

Applications

& Test Focus

Technical Specifications

| Parameter | Value |

|---|---|

| Max. Friction Torque | 2,000 Nm |

| Max. Axial Force | 20 N |

| Inertia J₁ | 1.0 kg·m² |

| Inertia J₂ | 0.1 – 0.75 kg·m² |

| Rotational Speed Difference (Δn) | Up to 7,000 1/min |

| Lubrication | Internal oil cooling + external unit with heating & cooling |

| Clutch Cooling | Directed internal oil flow |

| Configuration | Fixed outer carrier, rotating inner carrier |

| Optional | Creep drive system for low-speed clutch engagement analysis |

Proven Platform with Academic Validation

The FARAX®-KLP260 is widely used in clutch material research and system testing. It has contributed to over 10 dissertations and 10+ scientific publications and is operated on five dedicated test benches. It is compatible with KUPSIM software, which models temperature dynamics for deeper data analysis.

Whether you’re validating production quality, benchmarking materials, or exploring design improvements – the KLP260 provides a repeatable, trusted foundation for your test strategy.

Use Cases at a Glance

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.