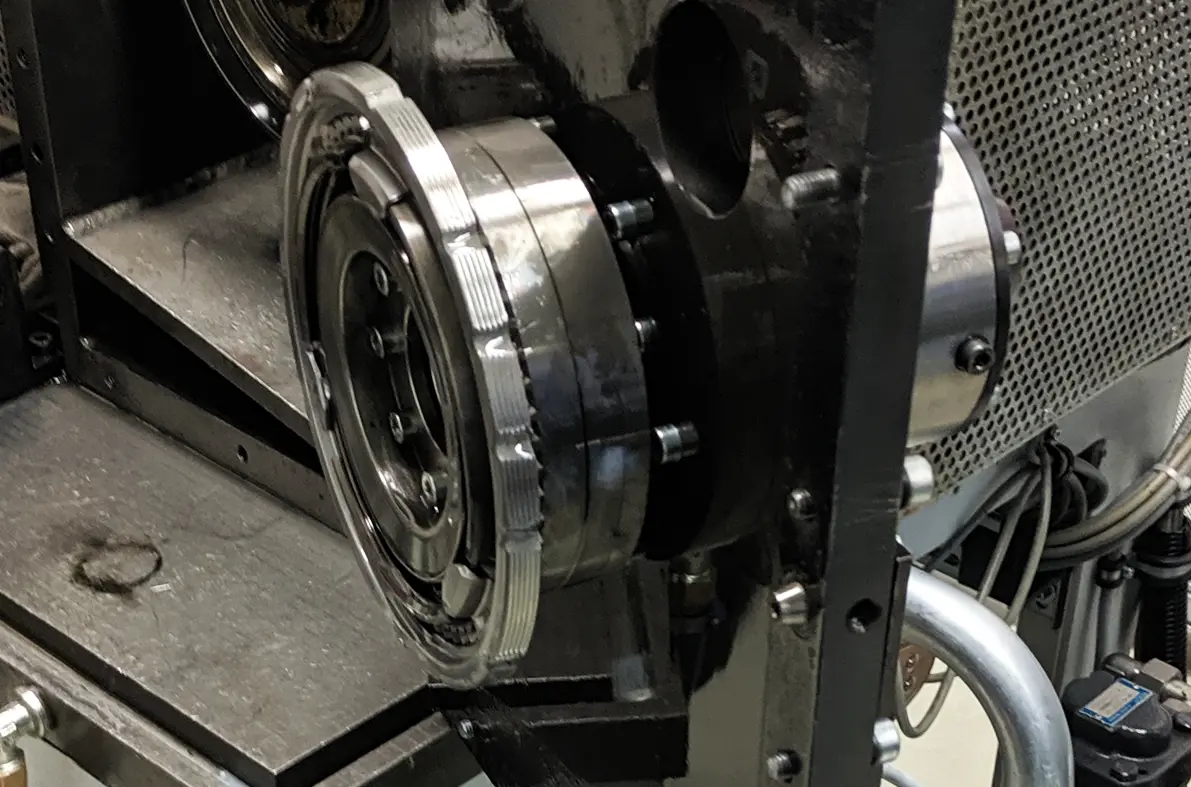

The FARAX®-SSP180 is a high-precision test bench for the evaluation of synchronizer ring performance, based on the well-established FZG methodology developed at the Technical University of Munich. It provides deep insights into the friction and wear behavior of synchronizer systems, using standardized and proven test cycles under realistic conditions.

Key Features

Applications

Application Areas:

Performance Criteria

-

Friction behavior

-

Wear characteristics

-

Synchronization time

-

Endurance life

-

Drag loss behavior

-

Overload capacity

Test Methods

Technical Specifications

| Parameter | Value |

|---|---|

| Max. samples | 2 simultaneously |

| Max. speed | 5,000 rpm |

| Slip ring diameter | Up to 220 mm |

| Test temperature | 80 °C |

| Pressure stages | 3 – 5 – 7 MPa |

| Speed difference (∆n) | 800 – 1600 rpm |

| Endurance cycles | Up to 100,000 |

| Measurement output | µ (friction coefficient), torque, speed, axial force |

Materials Supported

-

Brass

-

Sintered friction linings

-

Organic friction linings (paper, carbon)

-

Molybdenum-based linings

-

Composite carbon types (e.g., Oerlikon EF5010, Miba MC331, Diehl DCM6)

Data & Visualization

Detailed output includes:

-

Torque curves and shift time analysis

-

µ vs. cycles trend plots

-

Signal trace plots for Fa, TR, µ, ∆n

-

3D performance maps (p/v, v = const., p = const.)

Optional: You can embed the infographic PNGs you’ve sent (e.g. charts, diagrams, material samples) to illustrate each test method visually.

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.