- Contact Us

- phone: +49 (0) 931 32298-0

- mail: info@innowep.com

- Friedrich-Bergius-Ring, 11

- 97076 | Würzburg | Germany

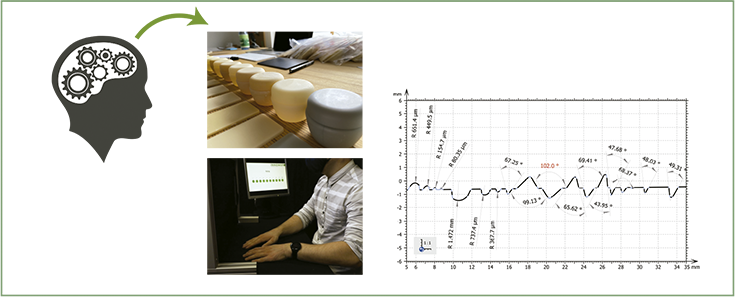

Haptic study and panel testing are techniques used by researchers to evaluate a product’s tactile features. In haptic studies, users are asked to provide feedback on the product’s physical feel, such as the texture, weight, and grip, by touching and manipulating the object. Panel testing involves a group of users who provide feedback on the product’s usability, such as how easy it is to use, and how intuitive the design is. Both of these techniques are useful for evaluating how a product will be perceived by potential customers, as well as for identifying potential flaws in the design.

What's Haptic?

• Feel good, or feel different?

• leather or plastic?

• a silky-soft and aromatic leather?

• sturdy metal?

• a smooth wood surface?

• easy to grip the control knob?

When you touch a material, the tactile feeling which is communicated between the human hand and the human brain will guide the customers to categorize the materials. For example, the touch evaluation of a leather surfacebecomes obvious that customer’s tastes are different and also change over time. People have various objectives towards leather, artificial leather and textiles. Therefore, what features are needed for designing specific materials with certain surface haptical characteristics?

We provide both panel test and quantative testing for your haptic study

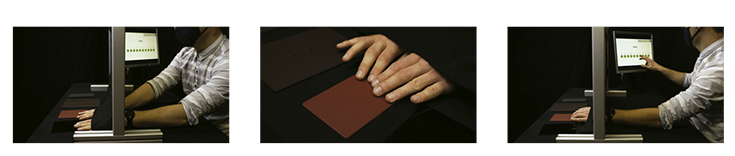

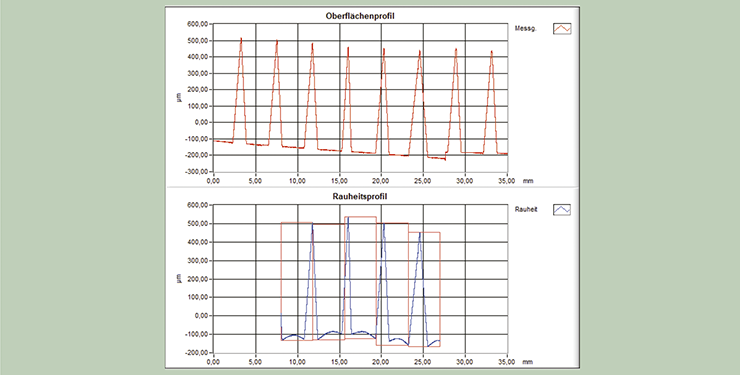

Our expertise is to find out what feels good to the touch, and why it is good, and this is HAPTIC – a feelable factors for quality, function and taste! To understand and design your haptical features, it is firstly necessary to build a test panel of certain amount of samples that could be compared with one another by the customers. Then the subjective results lead to a ranking for how the products are felt. The second step is to work out the quantative parameters and test conditions for physical measurements. These quantative results arising from these standard physical tests are then compared and correlated with various ratings that the assigned test customers have evaluated based on their subjective evaluations.

Examples:

When we design the interior materials for a sport car compared with a luxury sedan, the customer acceptance of various plastic or leather surfaces has quite different perspective. The subjective rating have shown that customers, for example, would prefer soft types of leather for a luxury sedan than hard leather surfaces. While people would choose hard feeling leather for a sport car. Therefore, we can utilize the general patterns for further development work. On the other hand, those physical measurement data will also provide the researchers with some clear conclusions about the material characteristics.

A second focus of the haptics is to determine the interaction between product’s “feel” and its perceived function. For example, the material design of soft contact lenses, the issues such as: How comfortable the contact lenses in the eyes? Is it too much friction or easily got iritating feeling in the eyes? Should the coatings be hard or soft?

Summary:

The haptics research, which involves designing and testing in several phases, permits human sensory qualities – those perceived by touch, sight, hearing and possibly even smell. Surely there is no good haptics or bad haptics, it is essentially depending on the tested object. For example, “a car has to look good”, or “a mobile phone has to feel good” , or “how the surfaces felt to the touch?”

Questions?

We are happy to help!

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany