Testing the fatigue performance of various types of bearings:

• Deep-Groove

• Angular Contact and Thrust Ball Bearings

• Spherical

• Cylindrical

• Tapered and Needle Roller Bearings

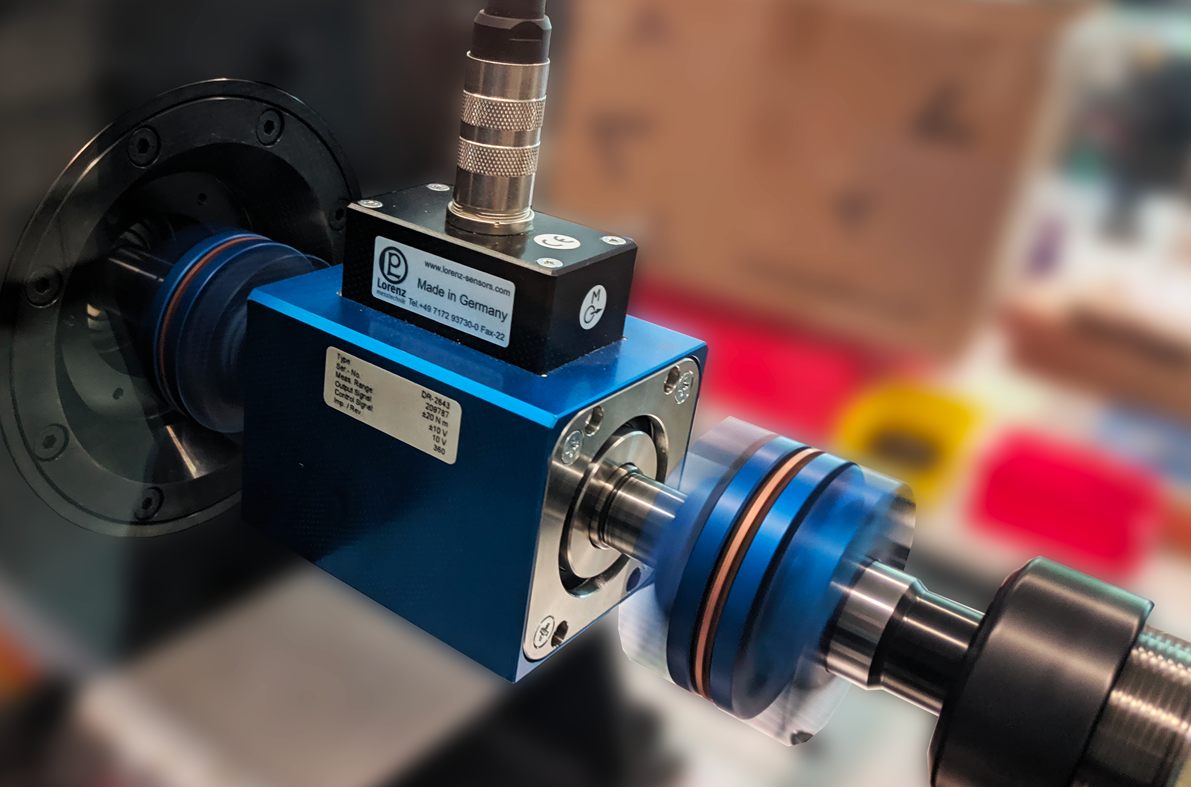

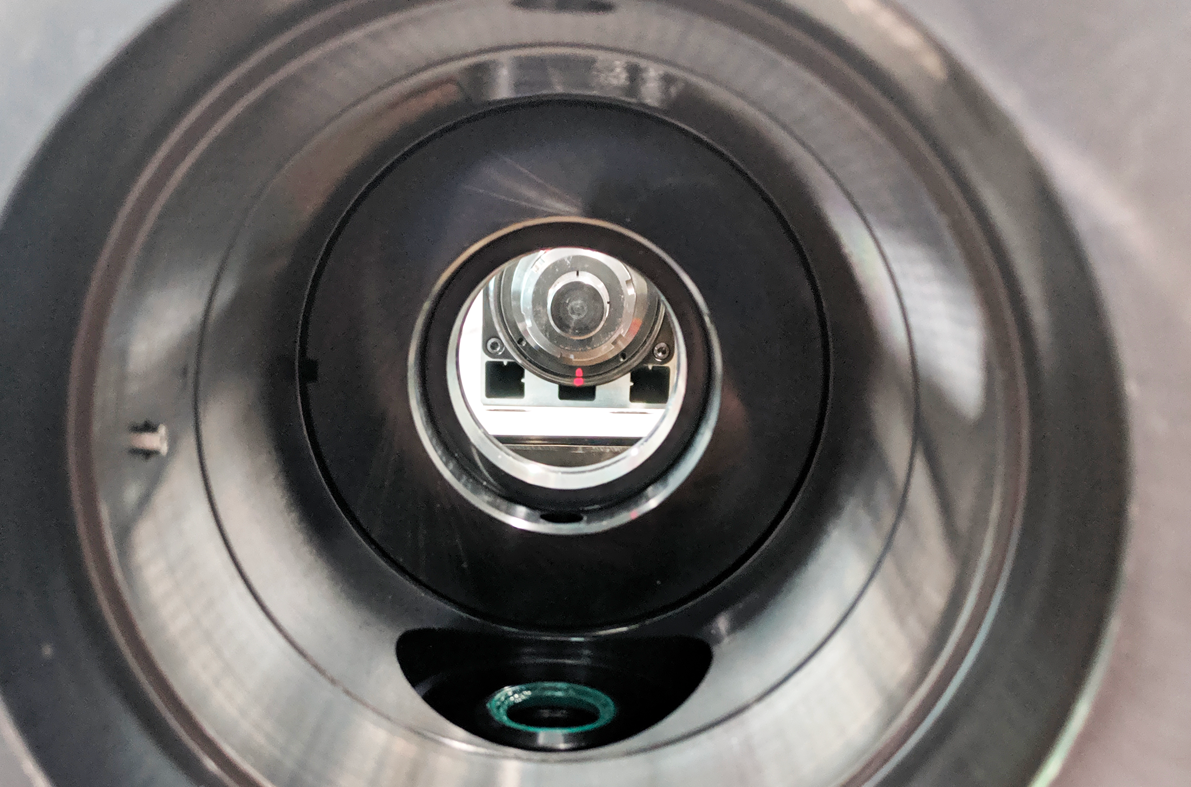

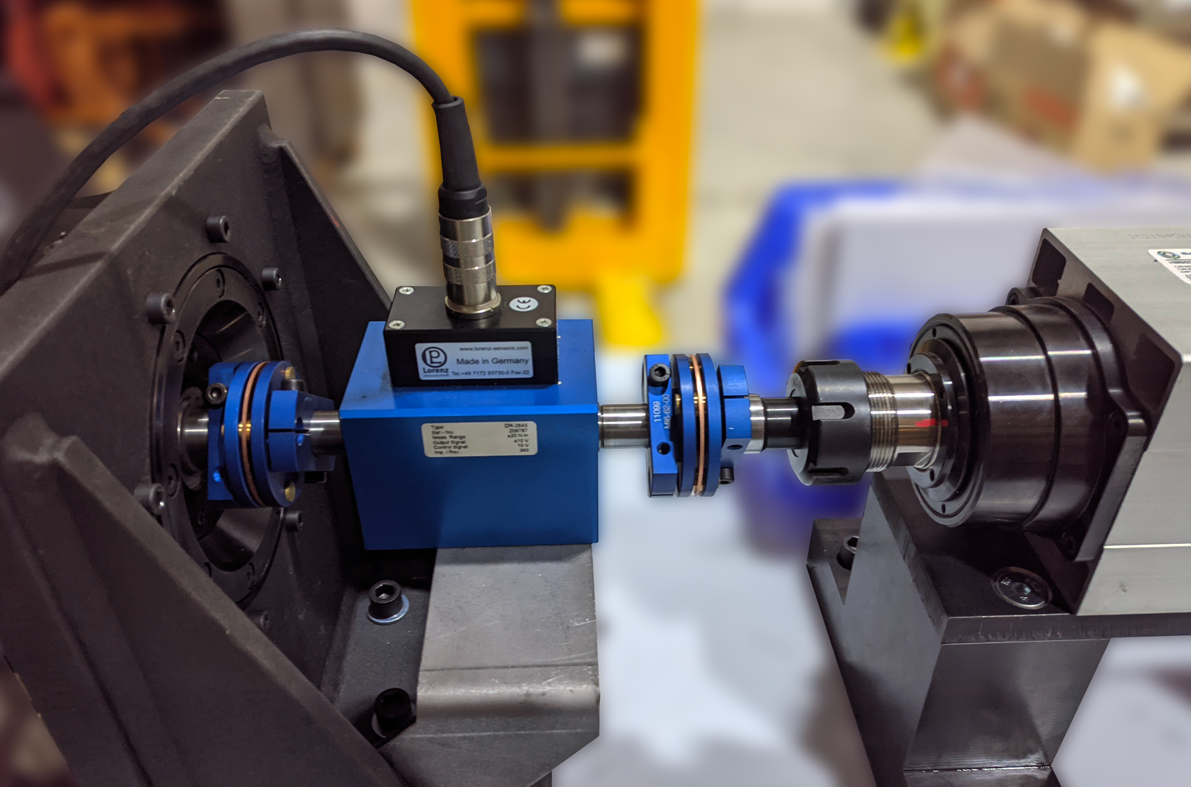

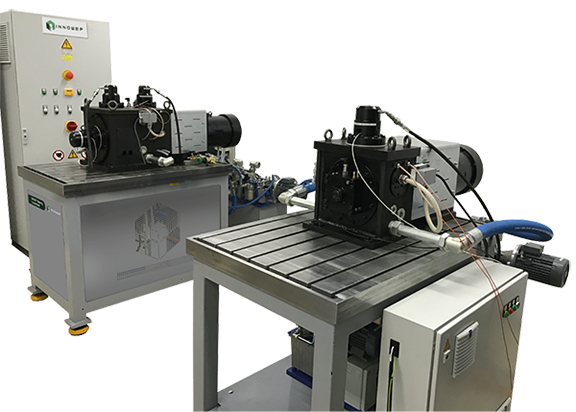

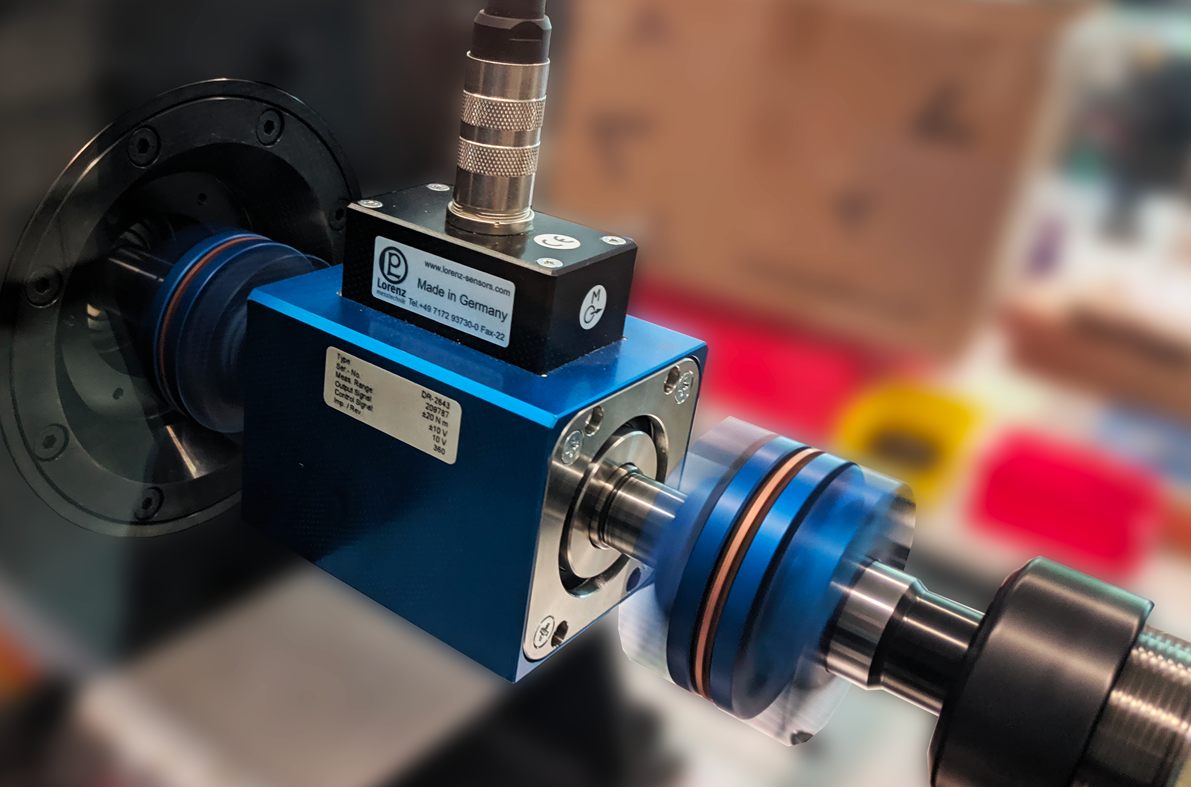

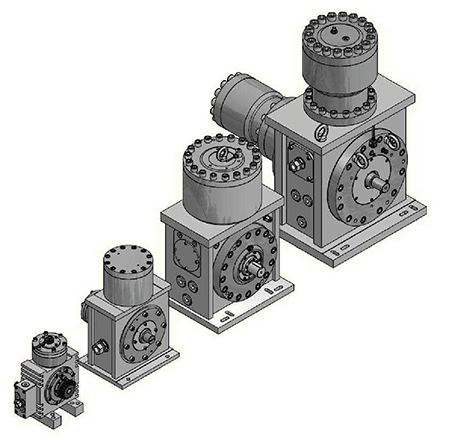

Bearing friction and fatigue test bench is an extension for testing customized bearings with different sizes or types due to our modular design capacity. The test bearing OD ranges from 30mm to 500mm and the test bench also provides multiple loading systems, including pure axial load, pure radial load, and a combination of both axial and radial load. The test bench is equipped with a super power motor which can run up to 19880 rpm. With a series of sensors installed, FARAX®-Bearing-C test bench can measure inline several parameters including torque, temperature inside the test head, temperatures in the lubrication unit, vibration, speed, load and many more.

Test bench includes a test bench with:

• Customized test head, connected with the drive motor via coupling;

• A measuring cabinet and a designated electronic cabinet;

• A lubrication unit with heating and cooling capability;

• Hydraulic unit for loading purpose;

• Necessary calibration tools and assembly tools;

• Radial and/or Axial Load

• Mechanical or Hydraulic loading system

• Torque measurement

• Grease or oil lubricated (optional spray or inject lubrication)

• Direct drive: 7,5 – 19.800 rpm adjustable depending on the bearing size

FARAX®-BEARING 7208

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany