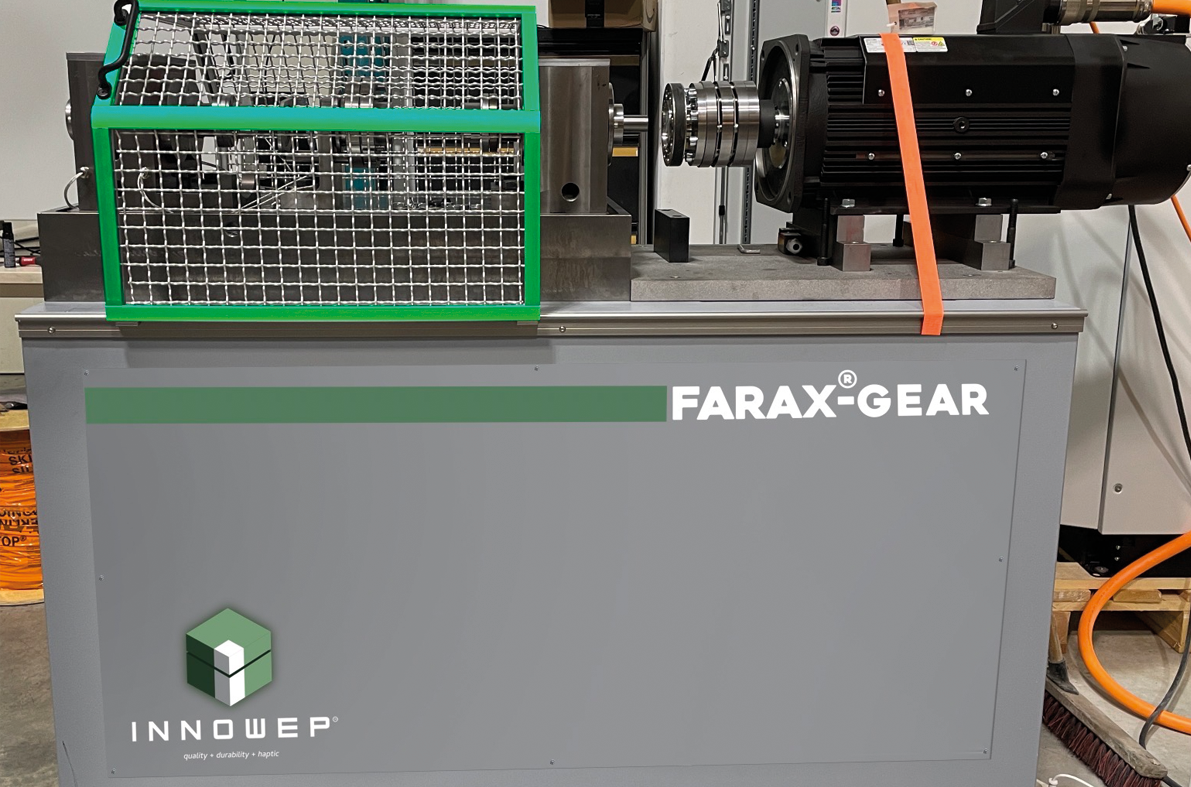

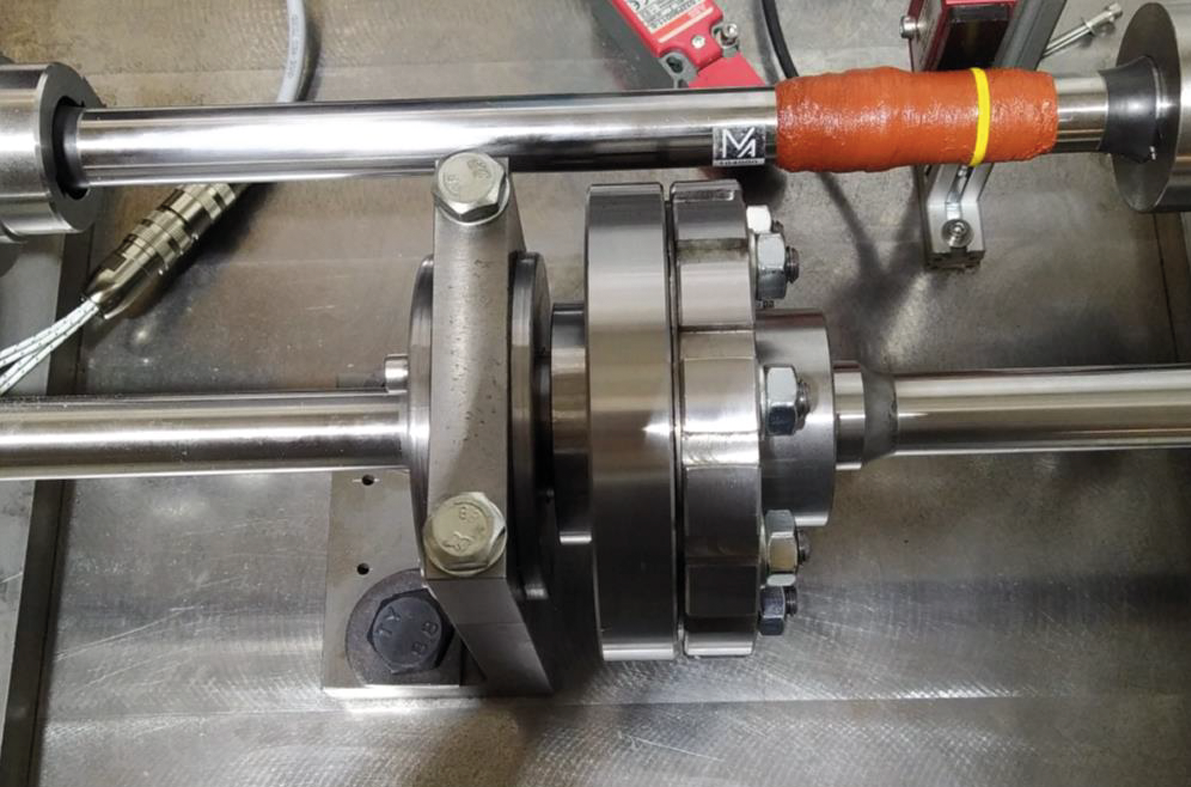

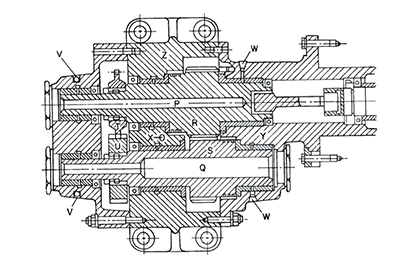

FARAX-Gear-HS test rig is designed to evaluate the scoring load capacity (or PZG Scoring Load Stage) of aircraft transmission gear oils, namely Ryder Gear Test according to FED-STD-791D / Method 6508.2. The special test gear is available and has been adopted for testing aircraft engine oil.

There are major components in aircraft engines, e.g. gears, that are lubricated under conditions of high speeds and extremely high temperatures. As a result, scoring damage can be likely to occur. With the expansion of our FARAX-Gear product from the standard ISO 14635 test rig to modified Ryder gear test rig which can run at much higher speed, up to 10,000rpm. The test adopts the special designed test gear under a pitch line velocity of v = 8.3 m/s, with a starting oil temperature of 90oC.

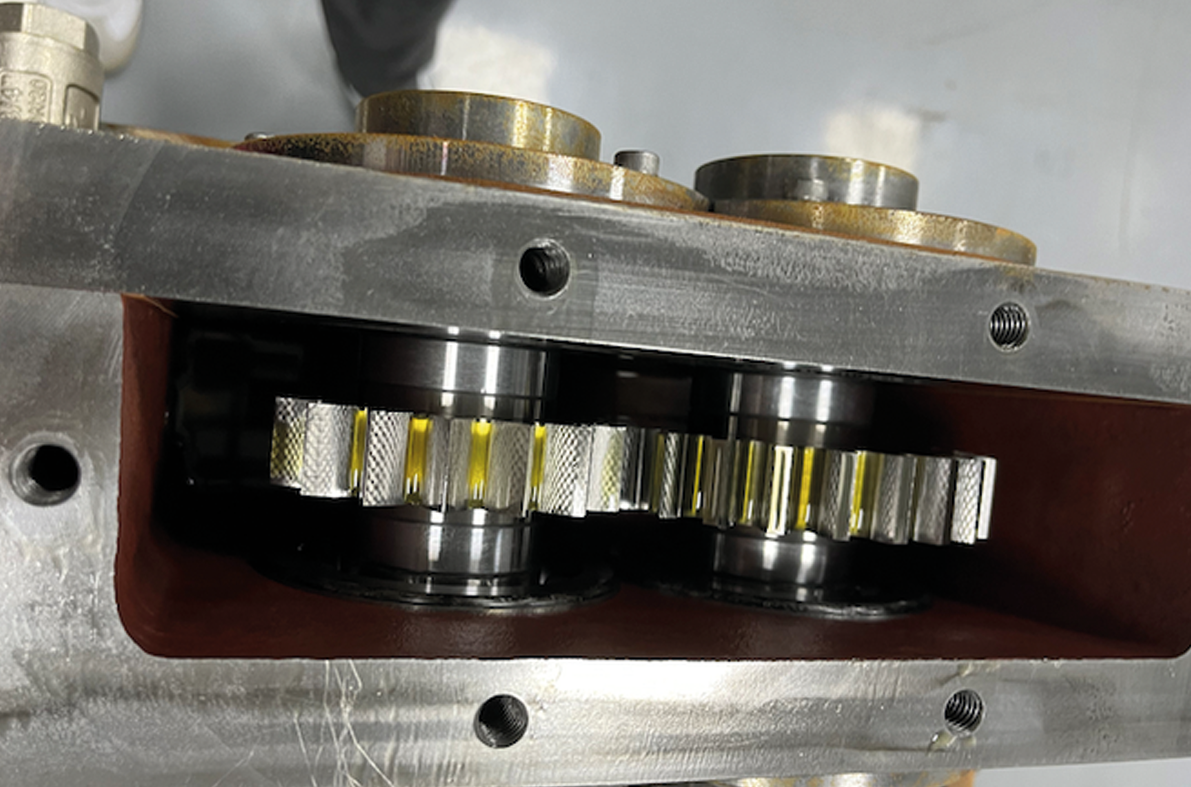

All types of gears,rolling element bearings,cam and followers and rolling contact variable ratio transmissions are typical mechanisms that depend on the transmission of force and power through elastohydrodynamic(EHD) contact to achieve successful operation and long lifetime. All such contacts are subject to wear during their long term operation and wear failures manifested by pitting, scuffing or scoring, smearing and abrasion. Additionally, the anti-scuffing or load-carrying performance of a lubricant has to be evaluated under "stressed" conditions.

In general, a hypoid gear oil will have both the extreme pressure type and anti-wear type additives whereas crankcase lubricants will be based on the multi-functional ZDDP anti-wear/anti-oxidant additive. The anti-wear additives react at lower temperatures than extreme pressure agents and ensure that the lubricant provides protection over a wide temperature range. A common feature of the procedures is to push the lubricated contact to a failure point and make a measurement of the"film rupture strength"or "load carrying capacity".

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany