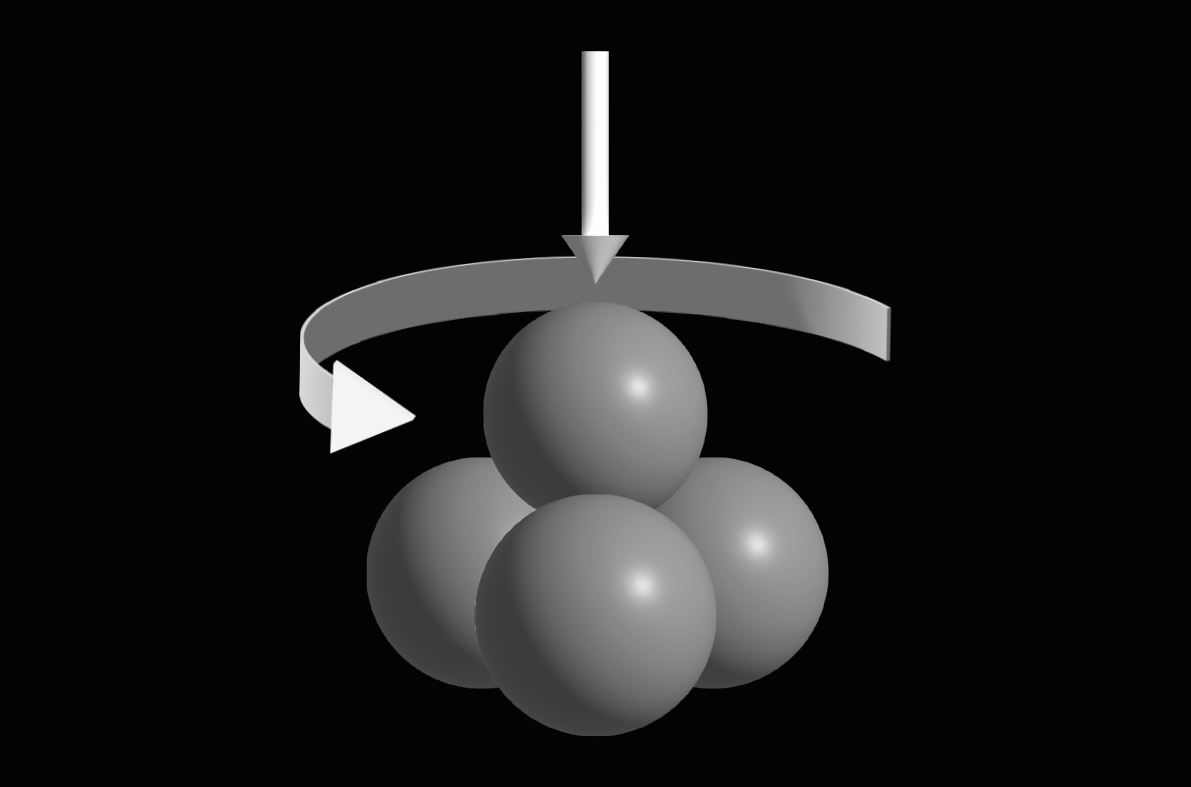

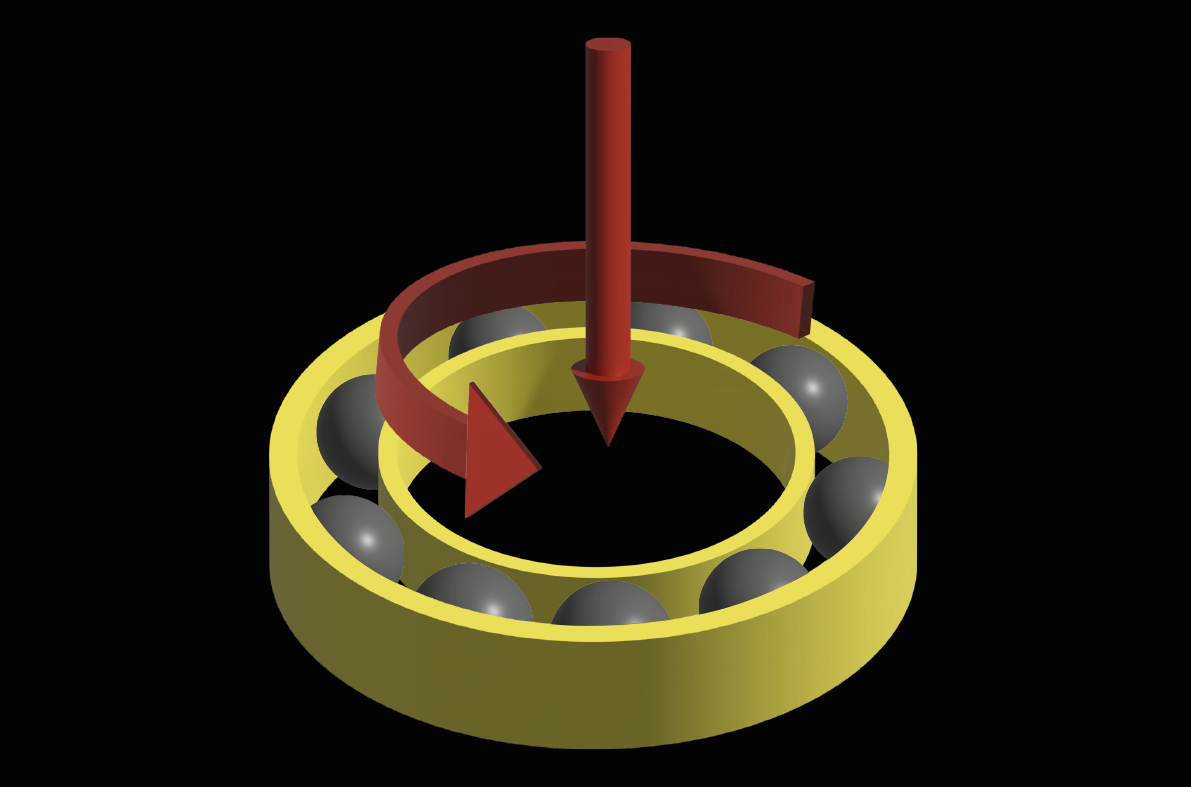

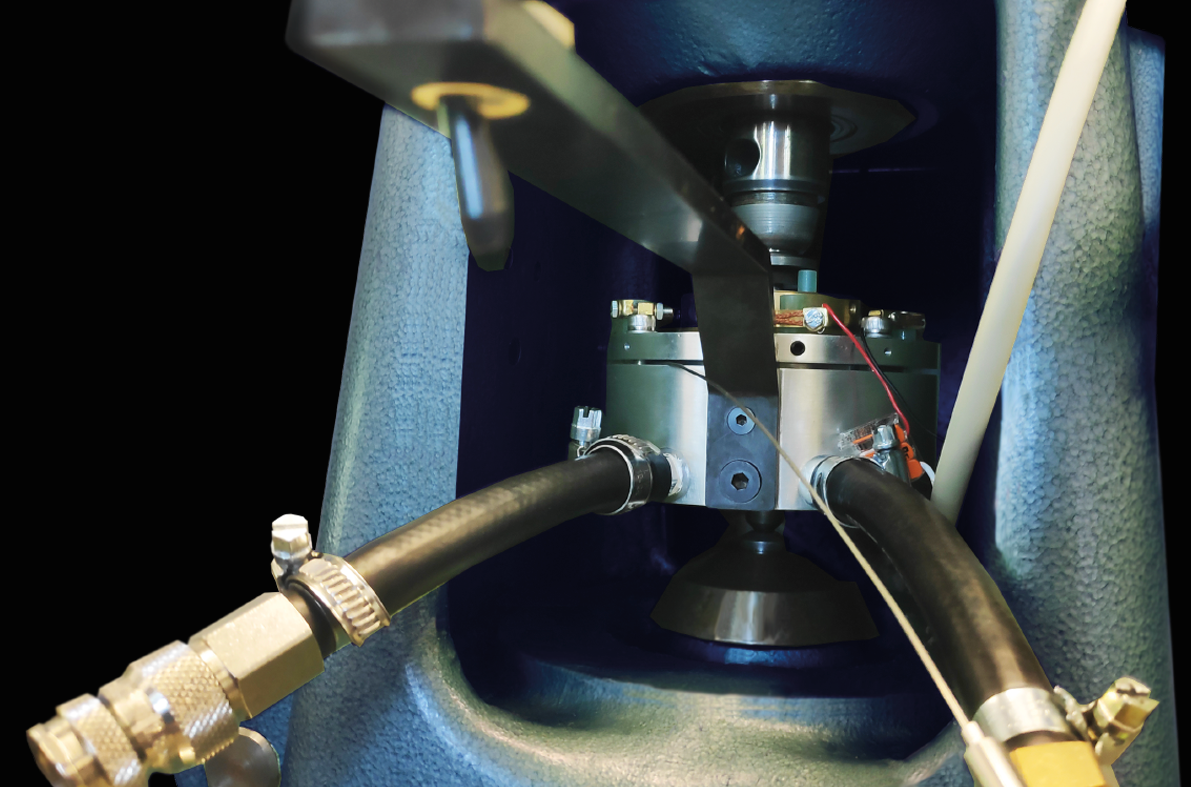

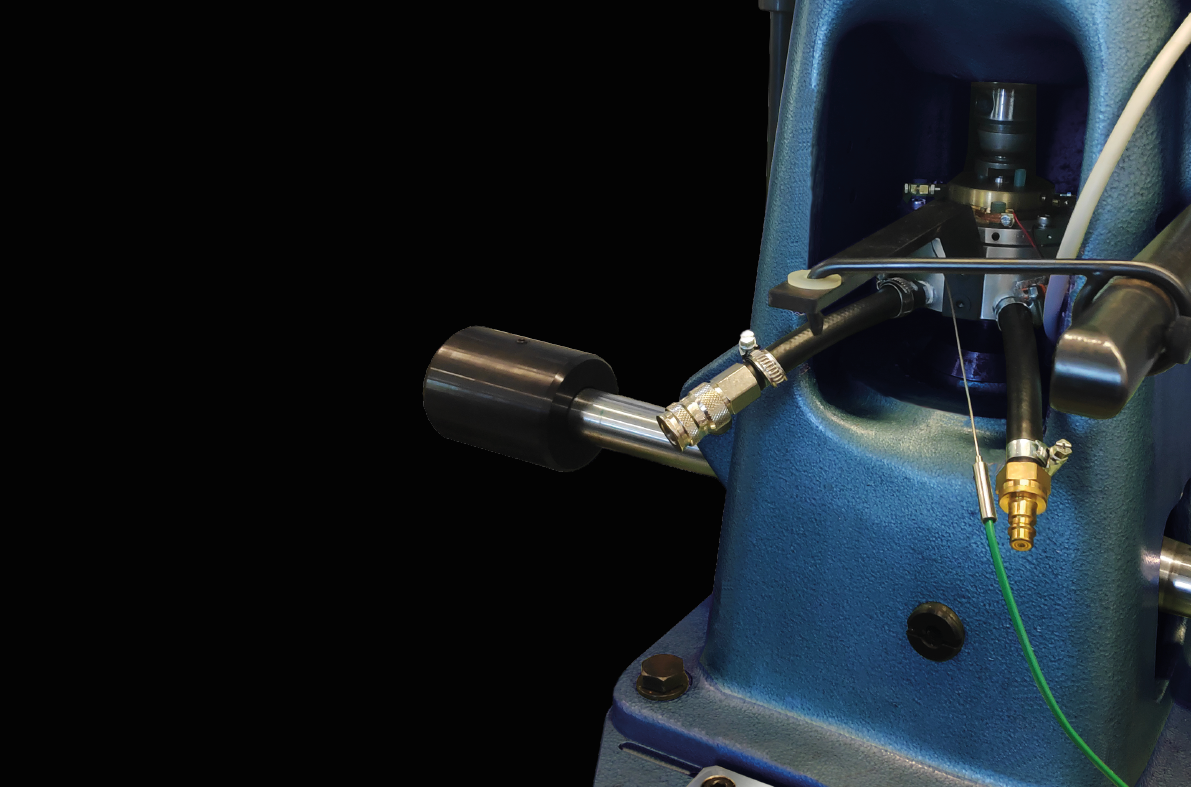

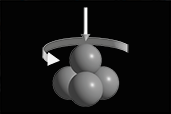

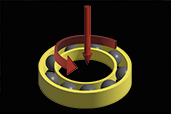

The standard Shell-Hansa VKA110 test machine complies with many ASTM, CEC and VW standard tests. The classical four-ball test consists of a rotating ball of a ball bearing pressed onto three similar stationery balls while applying a load. The friction torque, load, temperature can be recorded continuously. Wear is determined by optical microscope. Three other adapters which can perform various tests including shear stability test are available for evaluation of the shear strength of lubricants containing polymers according to DIN 51 350 Part 6. Additional tests are possible with numerous special adapters.

This standard Shell-Hansa VKA110 is used to perform tests in accordance with:

• ASTM D2266 Wear Preventive Characteristics of Lubricating Greases

• ASTM D4172 Wear Preventive Characteristics of Lubricating Fluid

• ASTM D5183 Determination of the Coefficient of Friction of Lubricants

• ASTM D2596 Extreme Pressure Properties of Lubricating Greases

• ASTM D2783 Extreme Pressure Properties of Lubricating Fluid

• IP 239 Extreme Pressure Properties: Friction and Wear Test for Lubricants

• DIN 51350/1-5 Testing Lubricants: Testing in the Shell Four-Ball Tester

• ISO/CD 11008 Petroleum Products and Lubricants – Determination of Extreme Pressure Properties of Lubricating Greases – Four Ball Method

The VKA110 is also equipped with a digital microscope with camera & software for damage analysis. This enables image capture and measurement of the wear scar on the test balls, without having to remove the balls from the test adapter

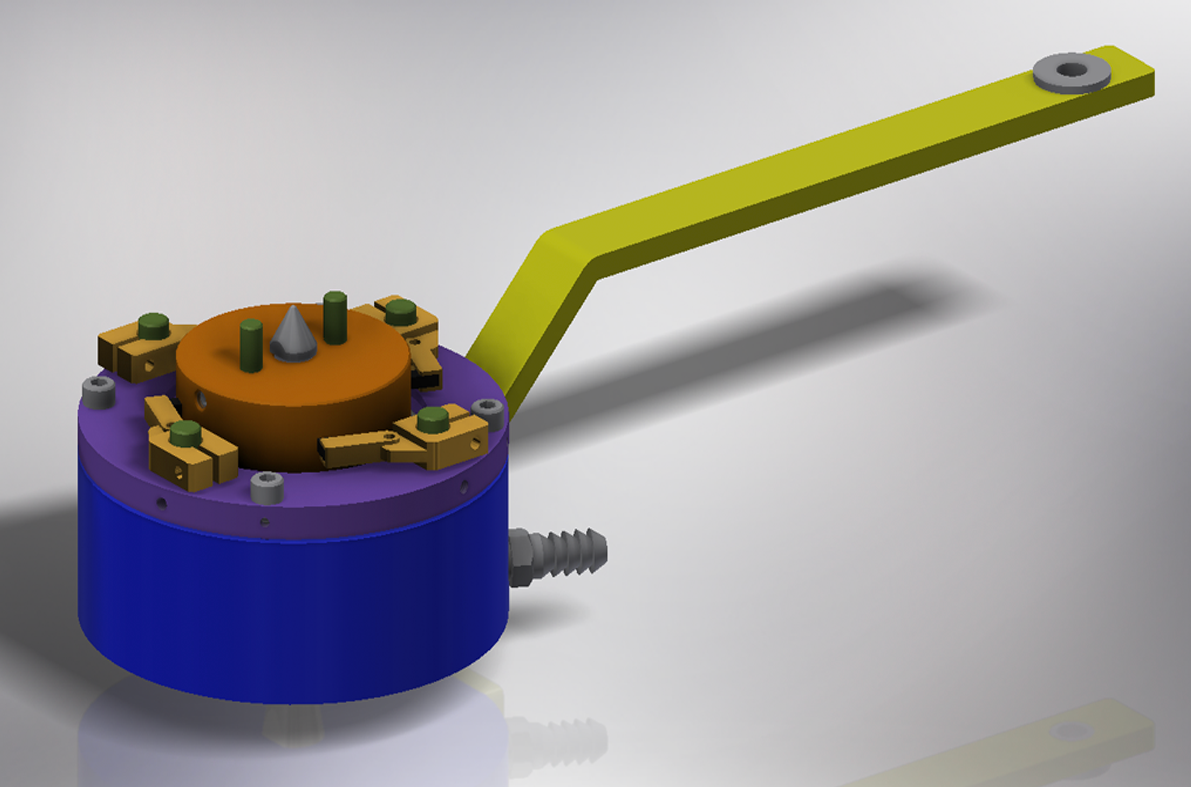

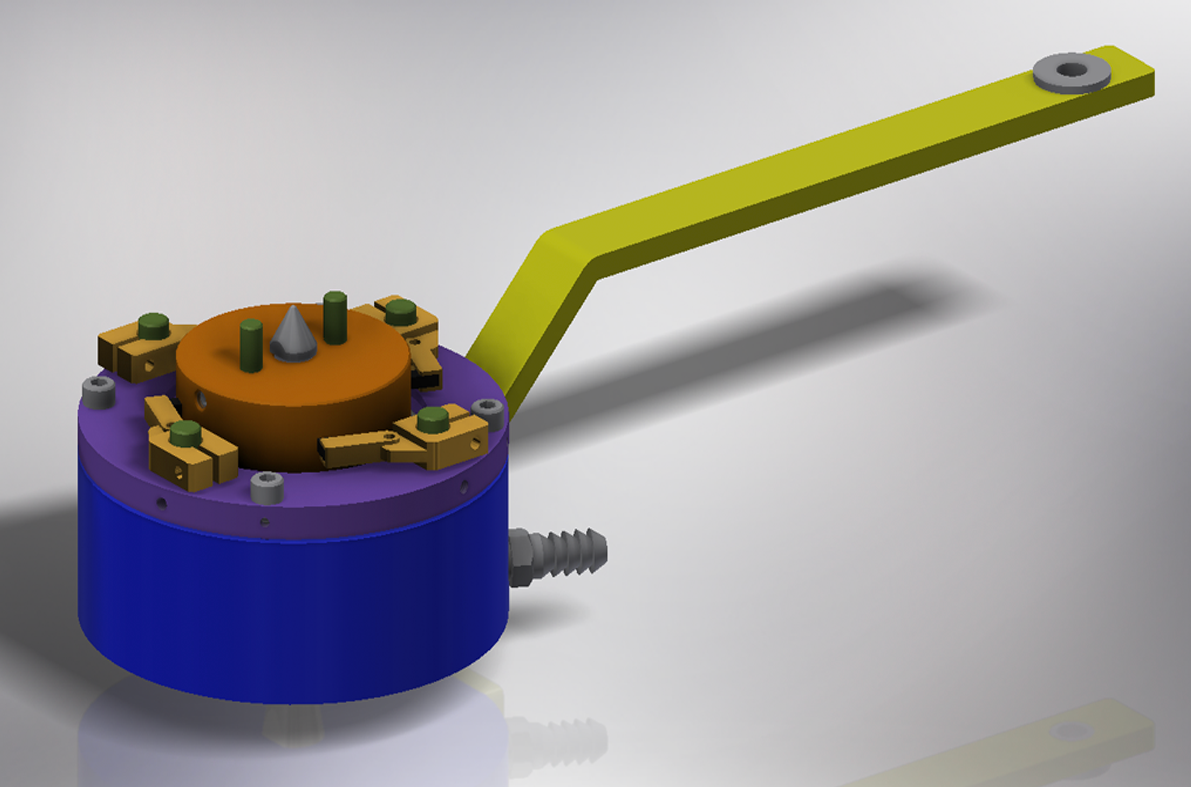

| FARAX®-BEARING-VKA |

• Speed: 10 to 5800 rpm;

• Load 100 to 12000 Newton;

• Temperature -30° to 150 °C

• Movement types: Sliding, rolling

• Friction states: Mixed friction, EHD Contact Geometry Point, Contact Measurements Friction Torque, Temperature, Transition Resistance, Calotte diameter

• Speed: 10 to 5800 rpm;

• Load: 100 to 12000 Newton;

• Temperature: -30° to 150°C

• Movement types: Sliding, rolling

• Friction states

• Mixed friction, EHD Contact geometry Point contact Measurements Friction torque, temperature, transition resistance, calotte diameter

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany