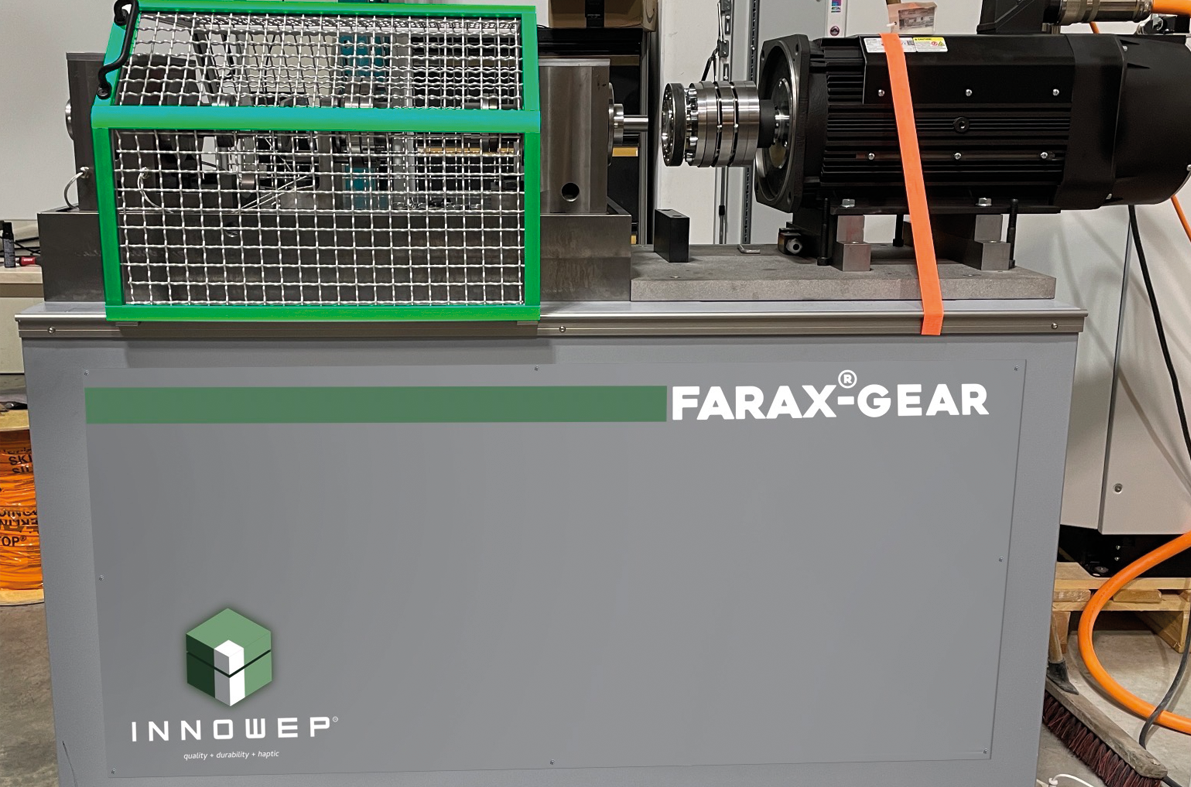

MFARAX®-Gear testing machine is a series of component testing rigs for both gear development and lubricant study, in traditional combustion engine and e mobility. The main test rig is designed for friction and fatigue performance for all kinds of gears, gearboxes, oil, additives and grease.

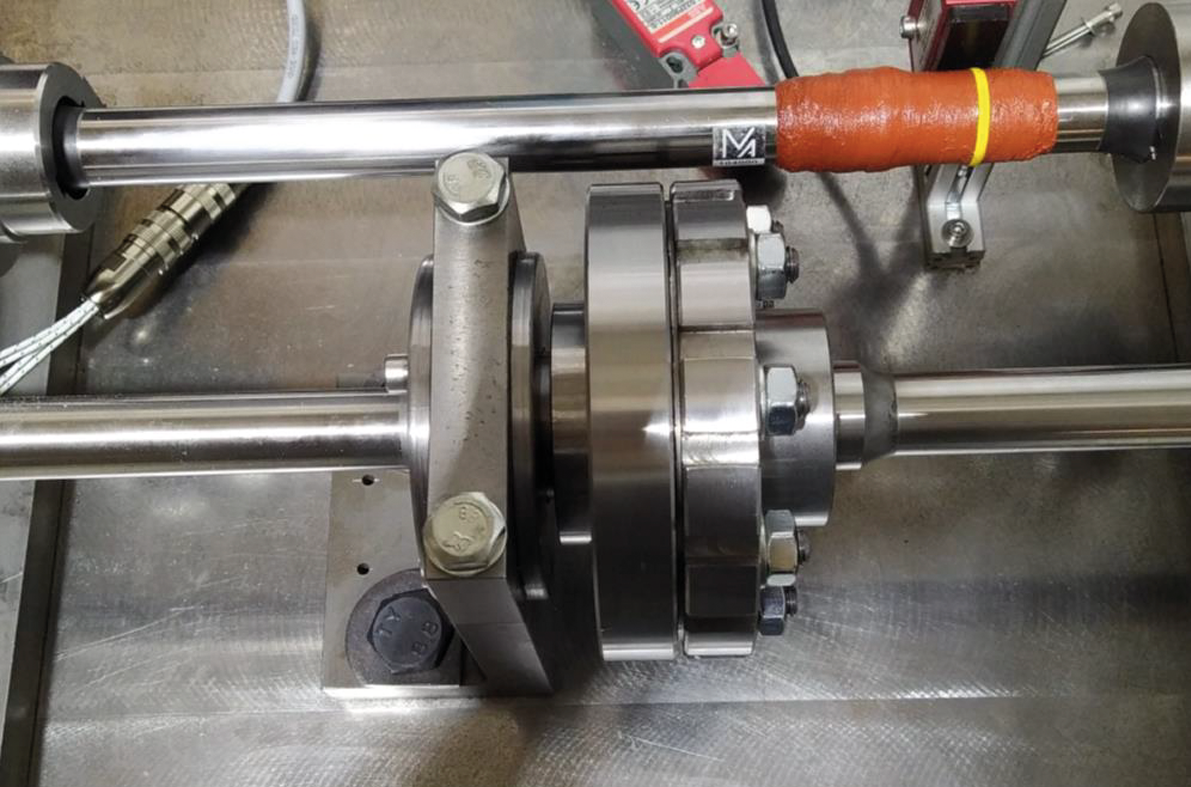

Key model of this FARAX®-Gear includes FARAX®-Gear-MU (acc. To DIN 51354/DIN EN ISO 14635/ ASTM DD5182 with upgraded mechanical load), FARAX®-Gear-HS (namely Ryder gear rig, equipped to run for high speed high temperature scoring test), and FARAX®-Gear-H high torque hydraulic load gear testing machine, FARAX®-Gear-C gear machine which a customized complete gearbox is integrated for testing. FARAX®-Gear series testing machines can meet the fatigue test of gears of different sizes, modules, gear materials and surface coating due to its modular design.

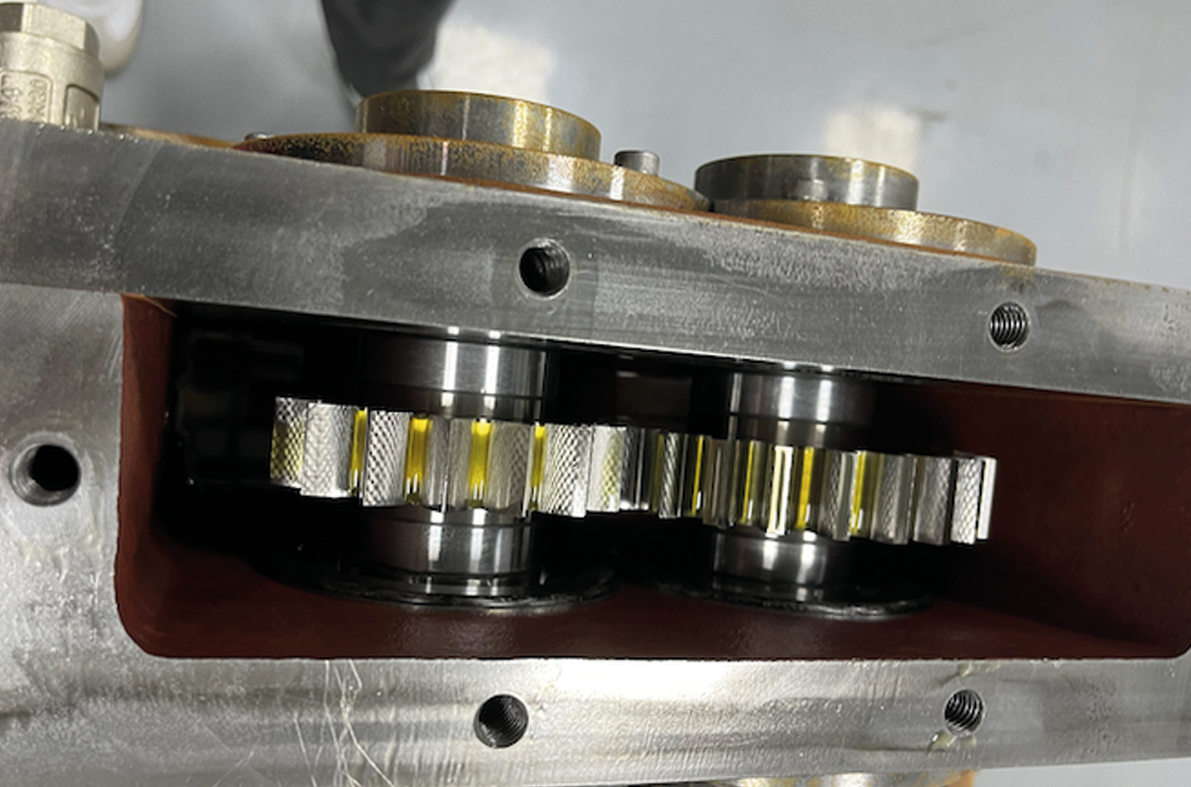

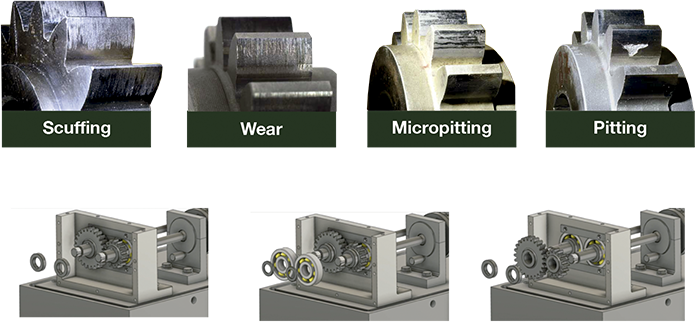

The normal operation of the machine is inseparable from the gears. During the meshing process, the gears have relative rolling and relative sliding. The action of these two kinds of force makes the shear stress of the pulsating cycle change deep in the surface layer of the gear. Under the repeated action of this shear stress, the tooth surface will cause local metal peeling and damage.

FARAX®-Gear gear testing machine series is a gear fatigue testing machine jointly developed by German Innowep company, adhering to the excellent quality tradition of German manufacturing, and integrating experts, professors and software engineers in mechanical engineering, material science, tribology and other fields.

Key model of this FARAX®-Gear includes FARAX®-Gear-MU (acc. To DIN 51354/DIN EN ISO 14635/ ASTM DD5182 with upgraded mechanical load), FARAX®-Gear-HS (namely Ryder gear rig, equipped to run for high speed high temperature scoring test), and FARAX®-Gear-H high torque hydraulic load gear testing machine, FARAX®-Gear-C gear machine which a customized complete gearbox is integrated for testing. FARAX®-Gear series testing machines can meet the fatigue test of gears of different sizes, modules, gear materials and surface coating due to its modular design.

This series of testing machines is mainly used to evaluate the performance of lubricants and simulate the movement form of gears in mechanical equipment, to study the fatigue performance, wear resistance and anti-skid performance of gears, and to provide boundaries and basis for gear design and application. The equipment can be easily supplied to meet the fatigue test of gears of different sizes, geometries and A20/A10/C type standard gears as well.

Innowep, Germany, originated from Würzburg, is a manufacturer of testing equipment for a full range of mechanical properties of materials and coatings. The main equipment includes fatigue, wear and friction testing machines for key components such as bearings, gears, and gearboxes. With nearly 30 years of rich experience in material surface lubrication and many other fields, customers cover major bearing and gear manufacturers around the world and related fields.

Other main product lines designed and manufactured by the company include bearing fatigue testing machines, various first-class material science friction and wear testing machines, and special fatigue testing machines for the electric vehicle industry.

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany