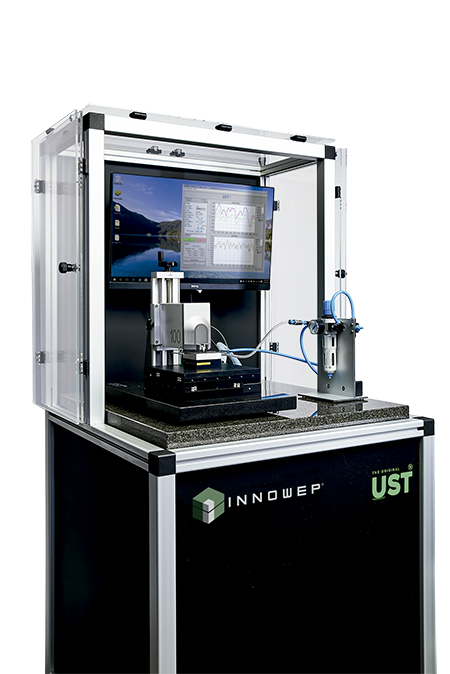

Universal Surface Solution within One System

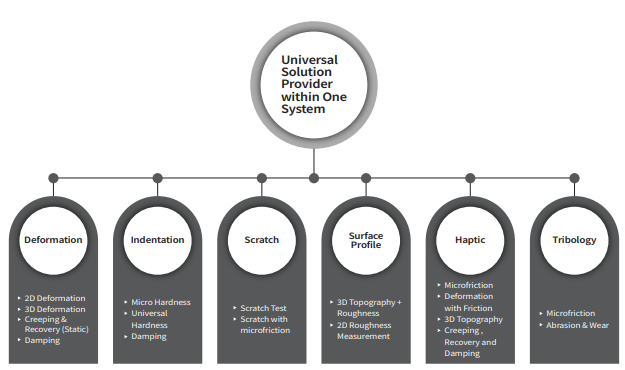

UST® is designed to deliver quantitative mechanical characterization of surface analysis within one open platform in nanometer resolution.

It serves best to the R&D center of our industrial partners and research institutes all over the world.

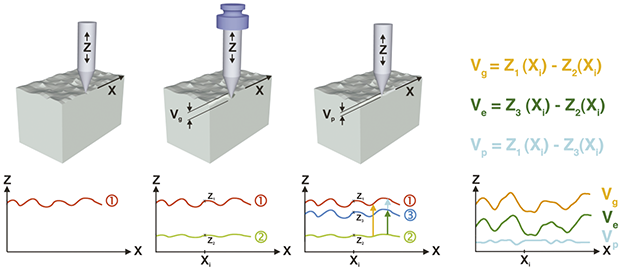

Built on a patented measurement protocol, the UST provides essential and reliable surface profiler solutions in both 2D & 3D in the nanometer resolution with a centimeter measuring range.

It perfectly closes the gap of a classical AFM and a macrometer surface analysis instrument.

UST® – Universal Surface Tester, is the only open multi-modular system that provides a complete mechanical testing solution for the evaluation of bulk materials and surface coatings. Over 10 measurements can be accomplished and over 60 different test tips have been developed to meet the diversity of your characterization requirements.

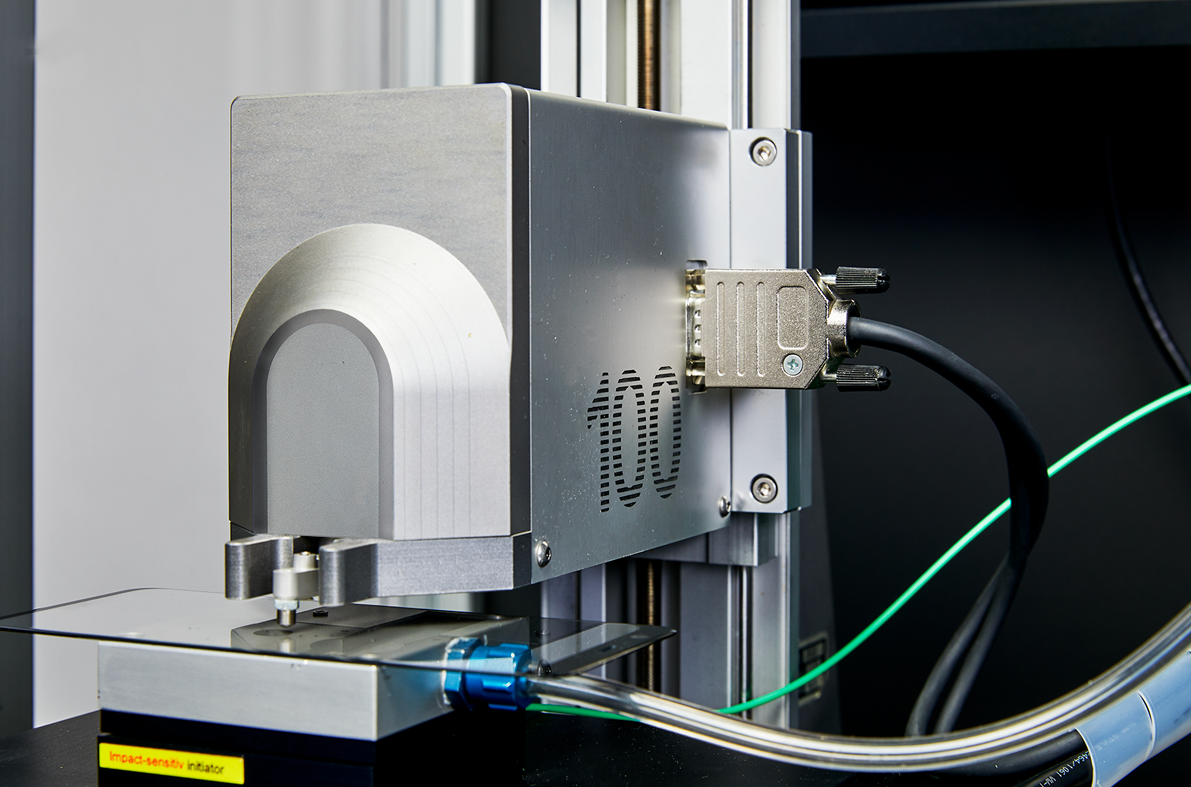

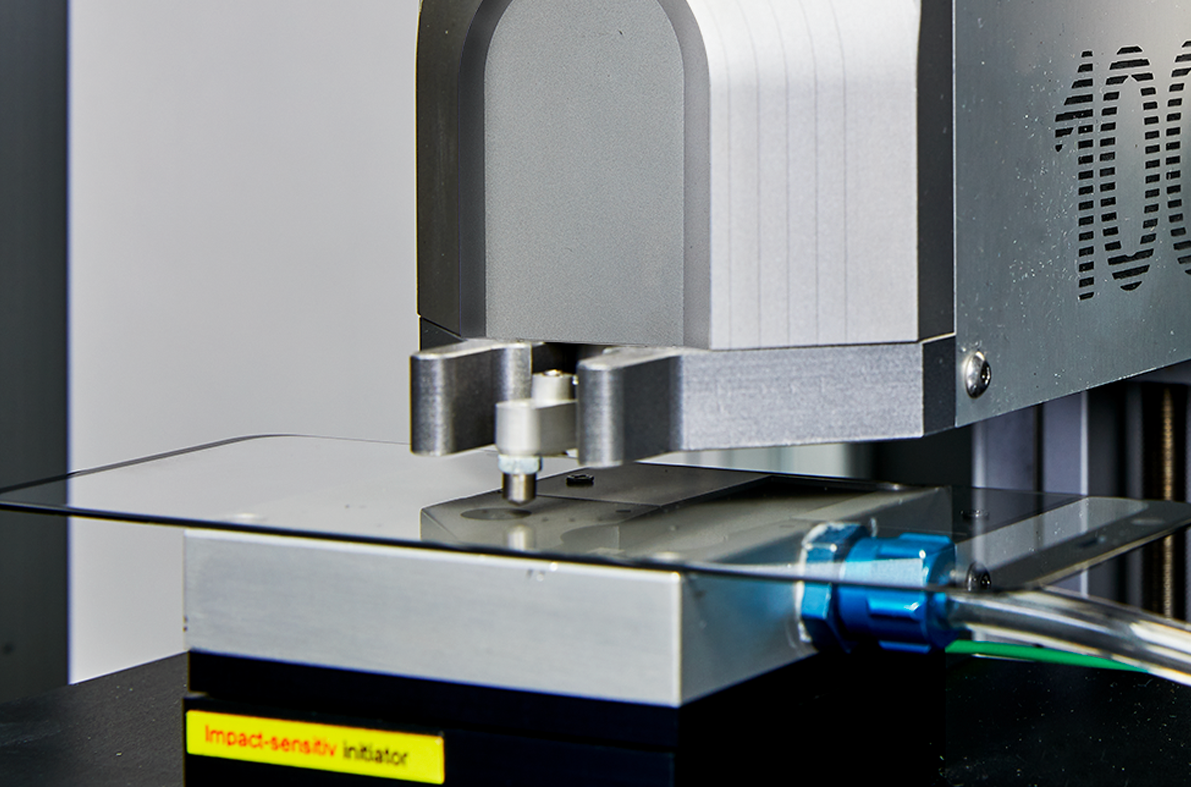

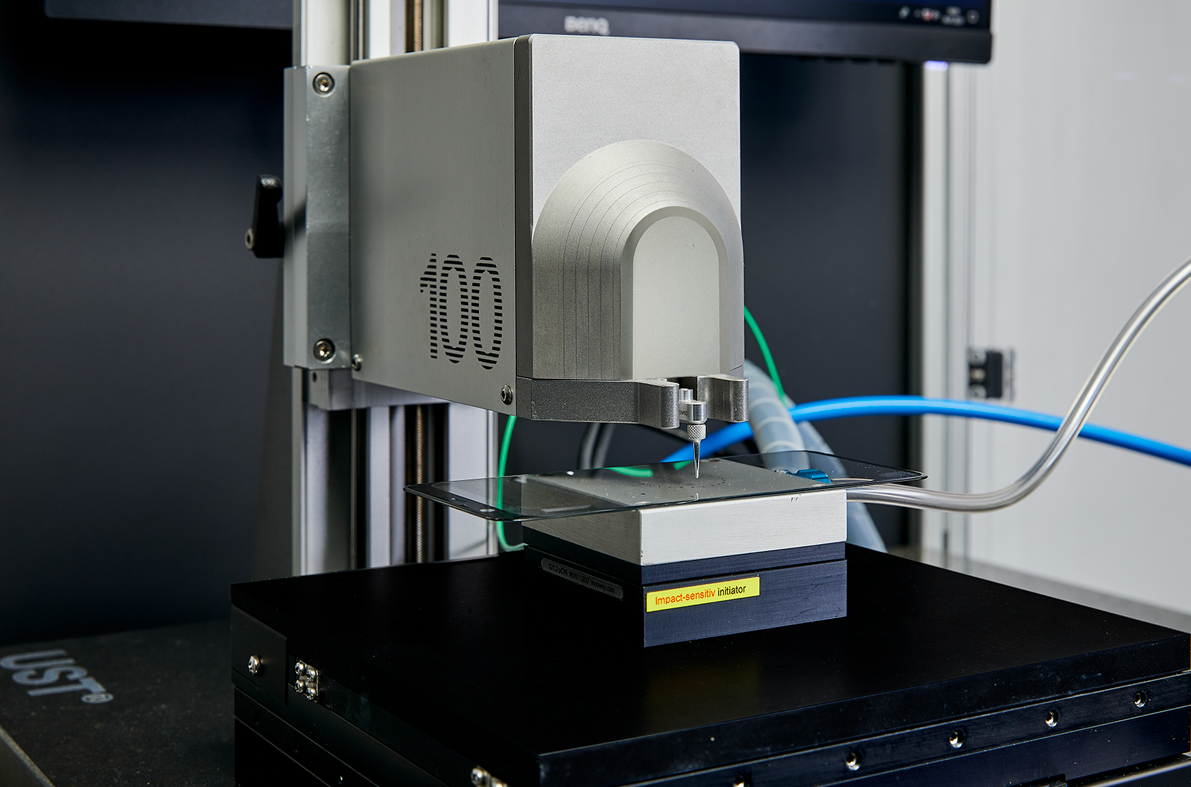

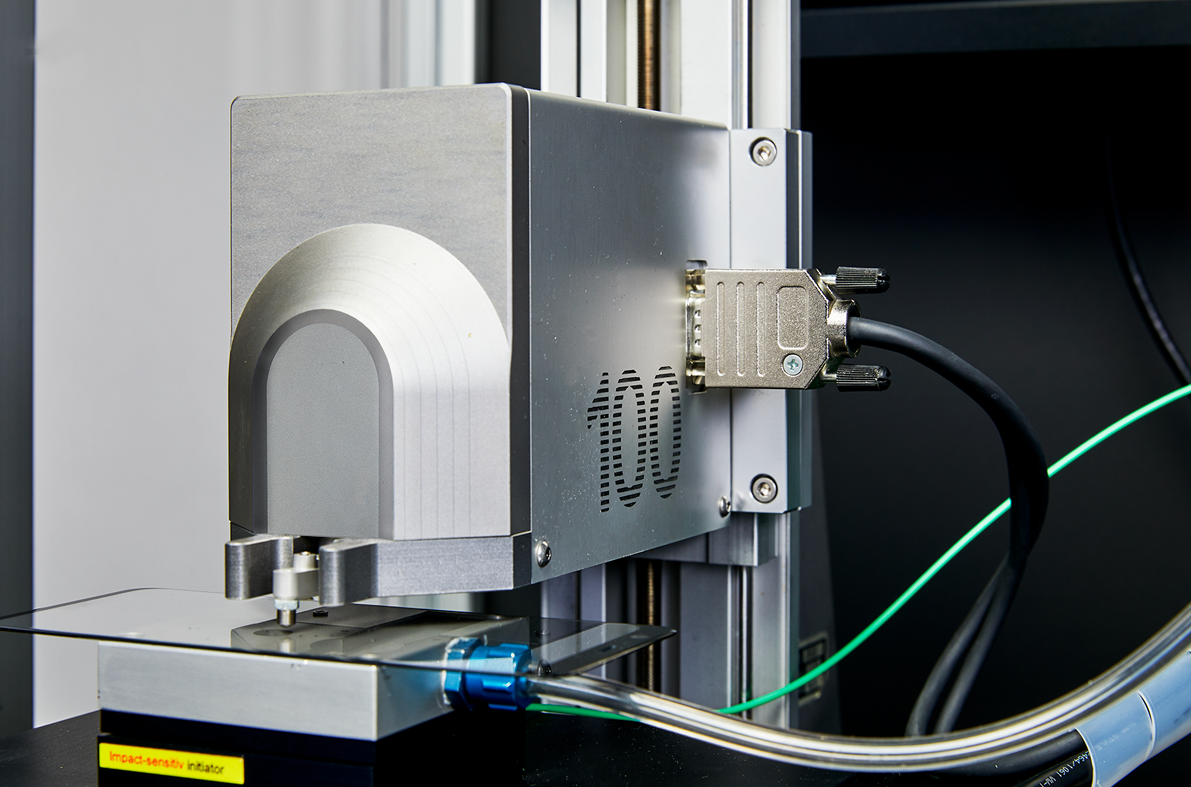

The basic unit of UST® has three versions: UST® 100 (loading range 1mN-100mN), UST® 1000 (loading range 10mN-1000mN) and UST® 50 (loading range 2-50N). The basic unit consists of floor-stand cabinet, measurement head with 3 tips, automatic X-Y table and data acquisition system.

Advantages

Among various kinds of commercial available in-line material property testing instruments, UST® is by far the only tester which closes the gap between the traditional macro-mechanical testing machines and nanoscale machines, e.g. AFM.

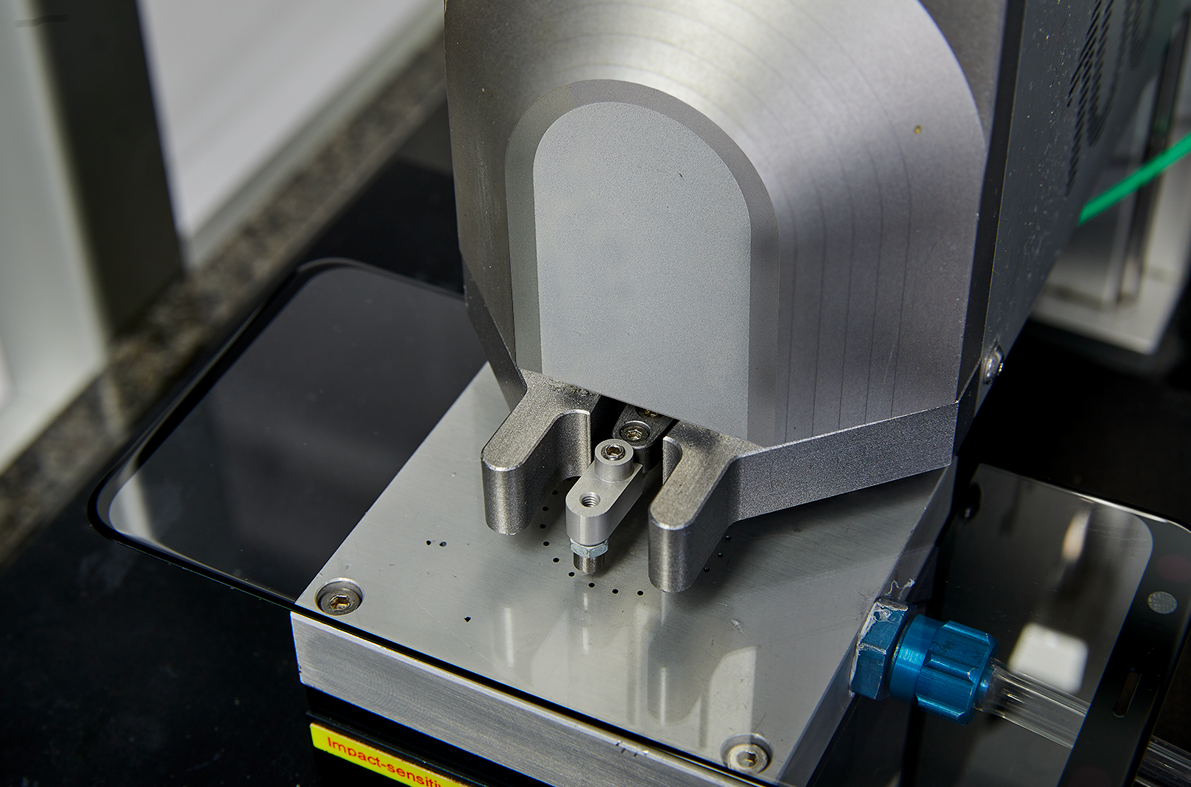

High precision load sensor combined with piezo actuator and active feedback loop control for real-time measurement of normal load and friction force

Options with different load range by easy exchange of measuring head

Automatic X-Y table with built-in motor for high precision profiling, the measurement area is up to 60 mm × 60 mm

High resolution table for high repositioning

• Accurate depth measurement with bigger travel range for all tests, up to 4mm in Z direction

• Advanced linear module with displacement sensor

• In-situ measurement with local resolution

• Steady control of speed, displacement and step load

• Automated video microscope with synchronized panorama

• Compatible to ISO, DIN and ASTM standards

• Real time data acquisition with full integration of images, data and graphics

• Easy sample preparation and tip exchange

• Customized tip choice for various applications

• Compatible with various environments: liquid, or humidity

Principle

The UST® measurement procedure consists of a mechanically scanning by a stylus on the sample surface along a straight line several times. During this patented MISTAN® procedure, the stylus is moved on the surface either without load or with a defined load.

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany