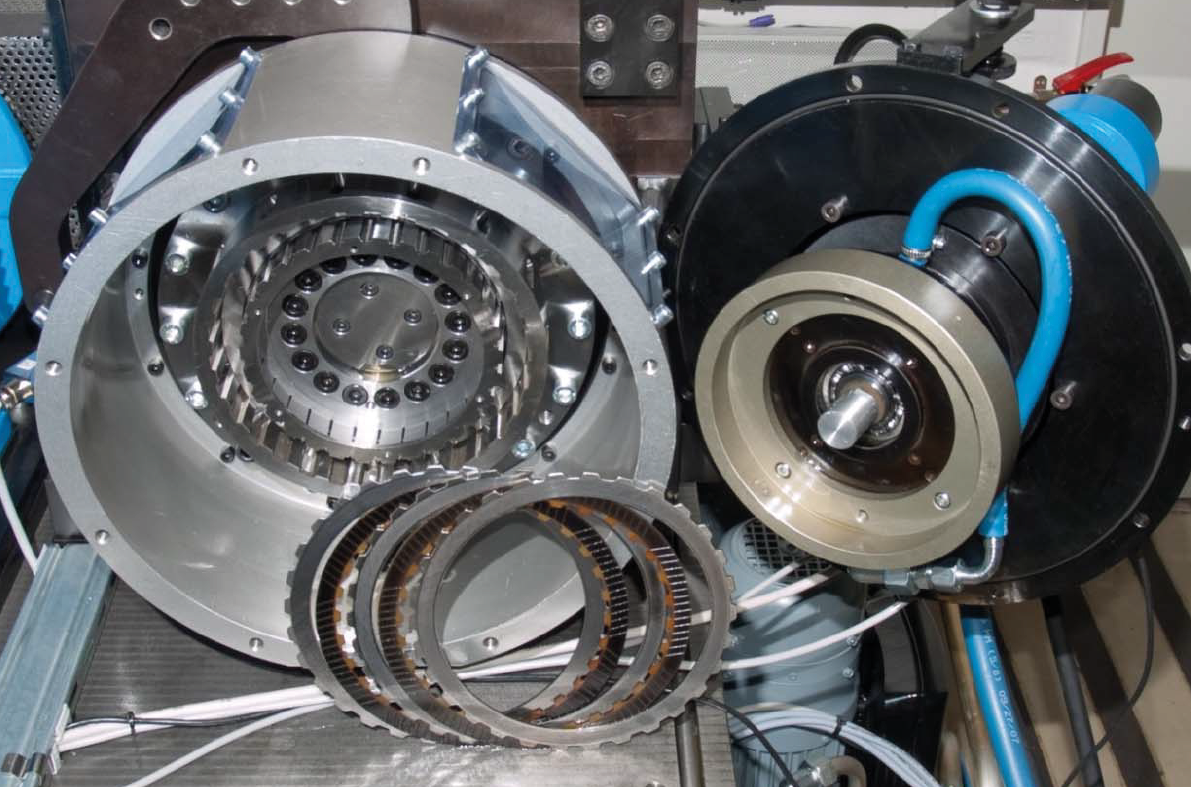

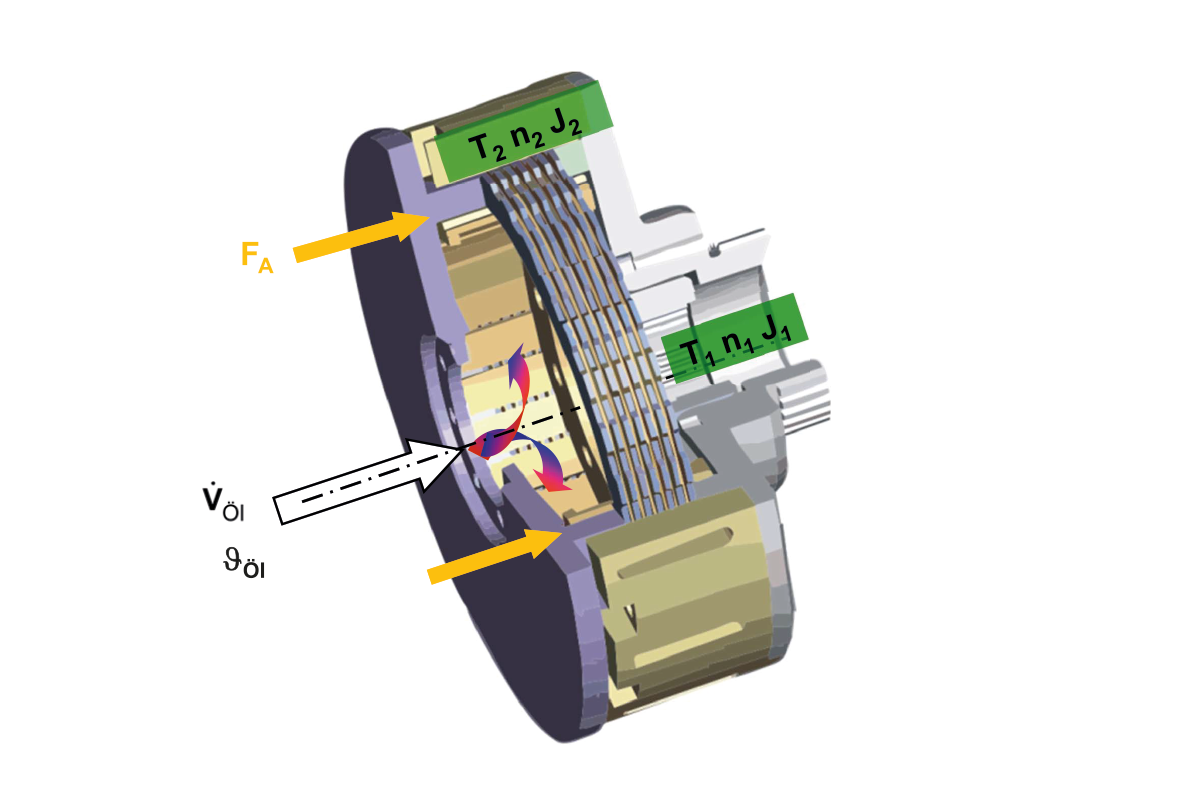

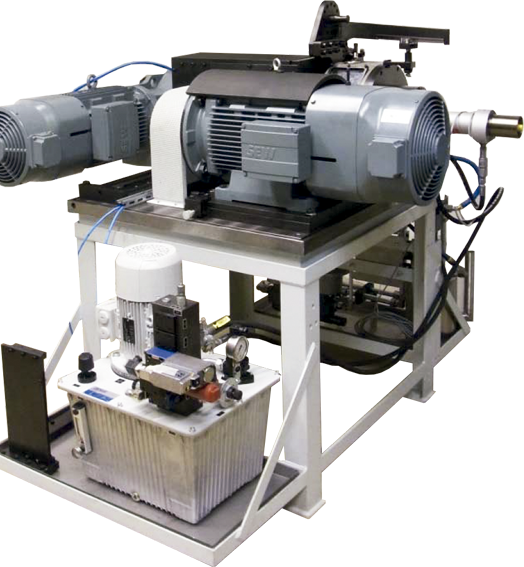

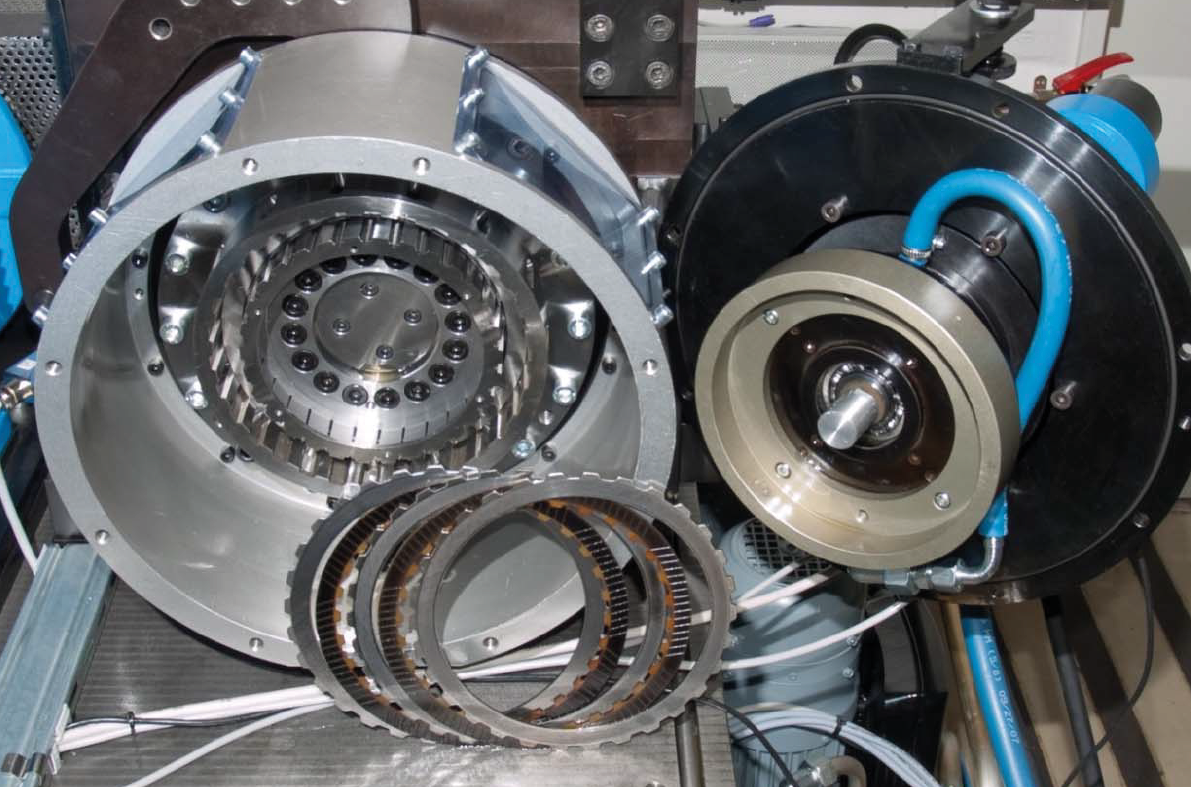

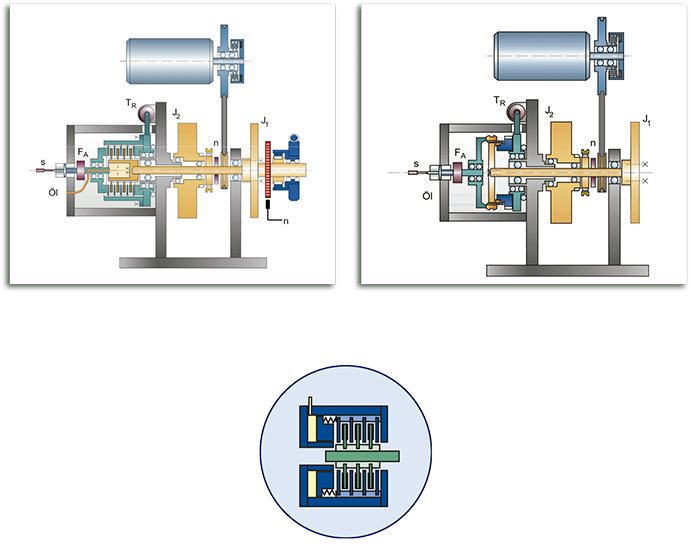

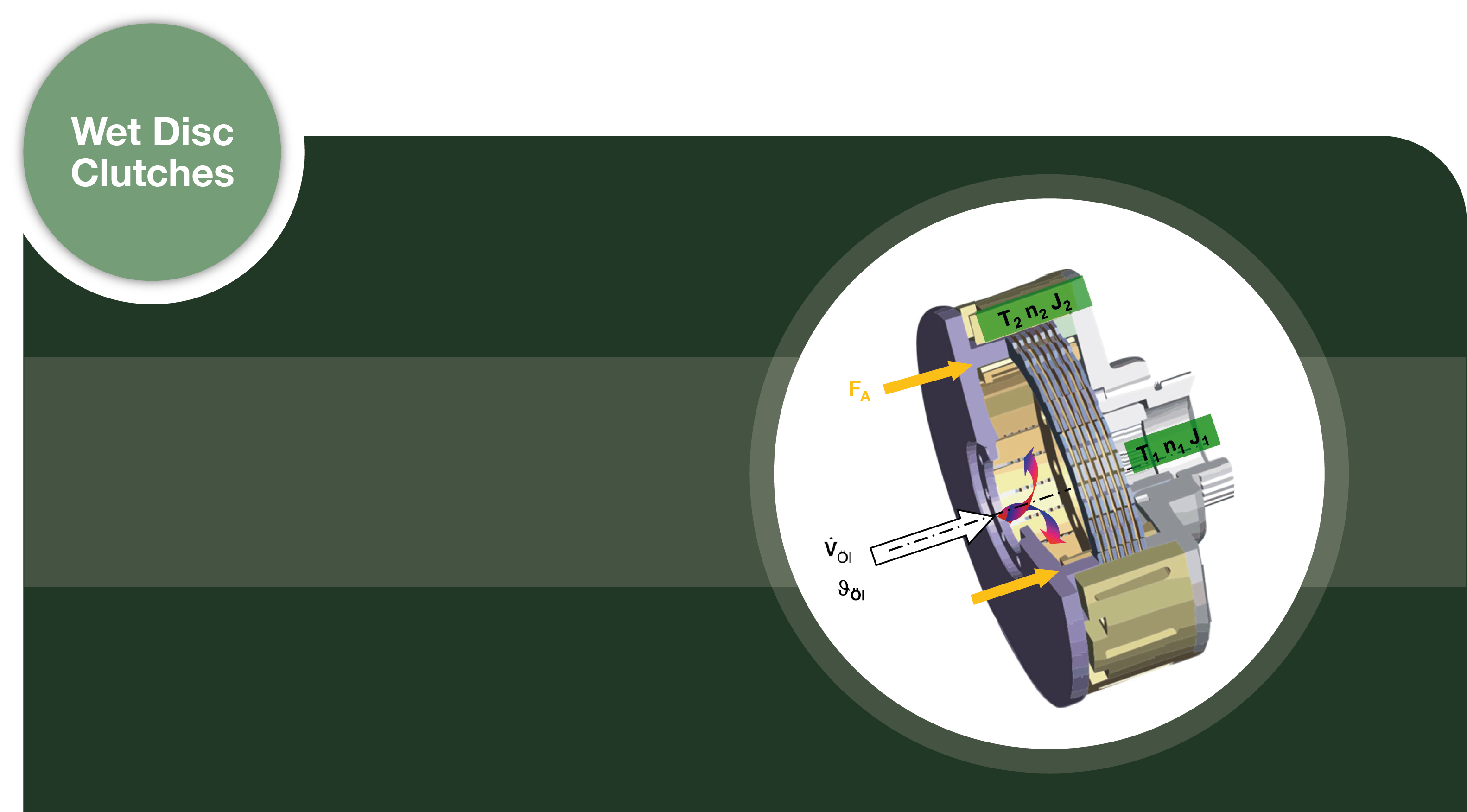

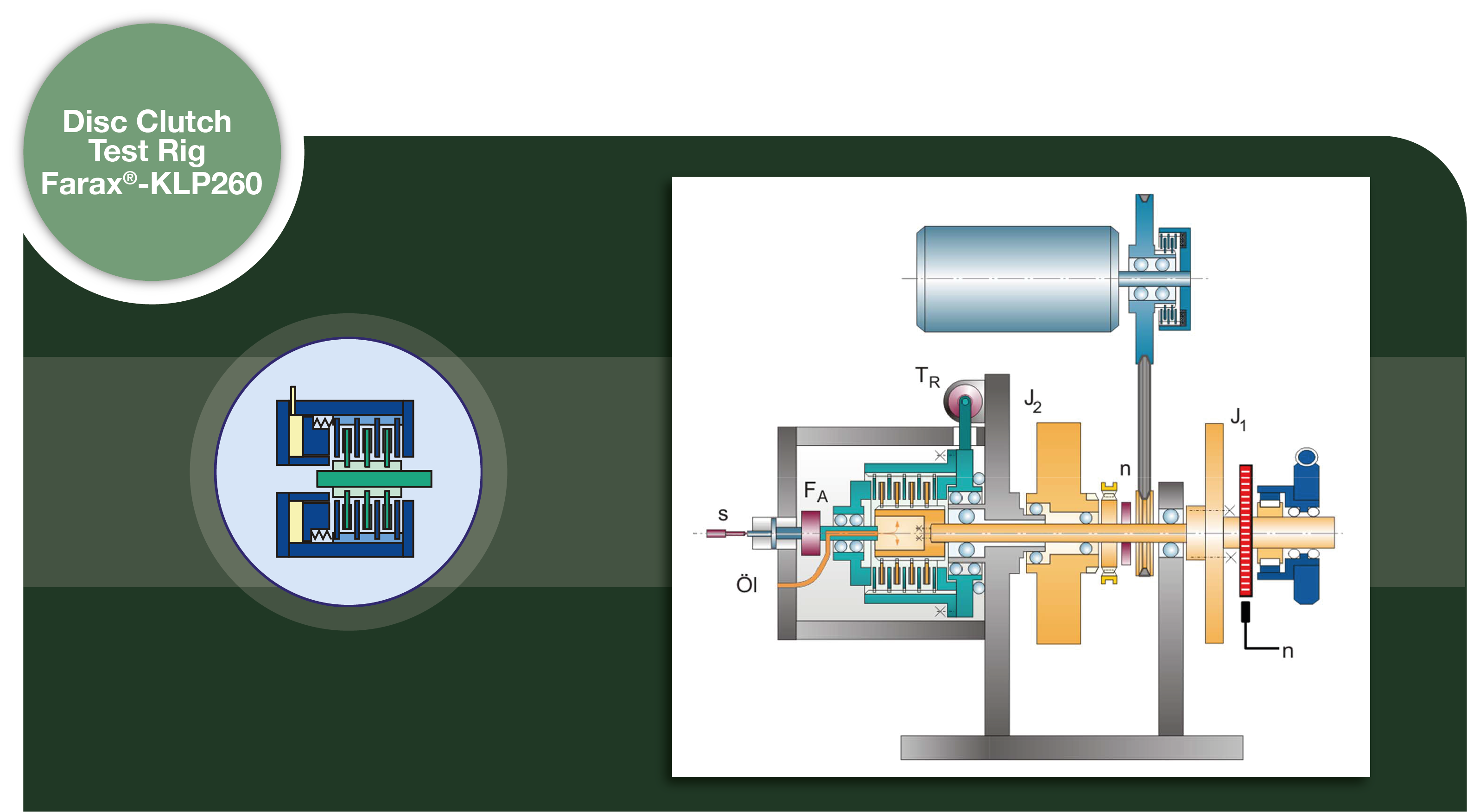

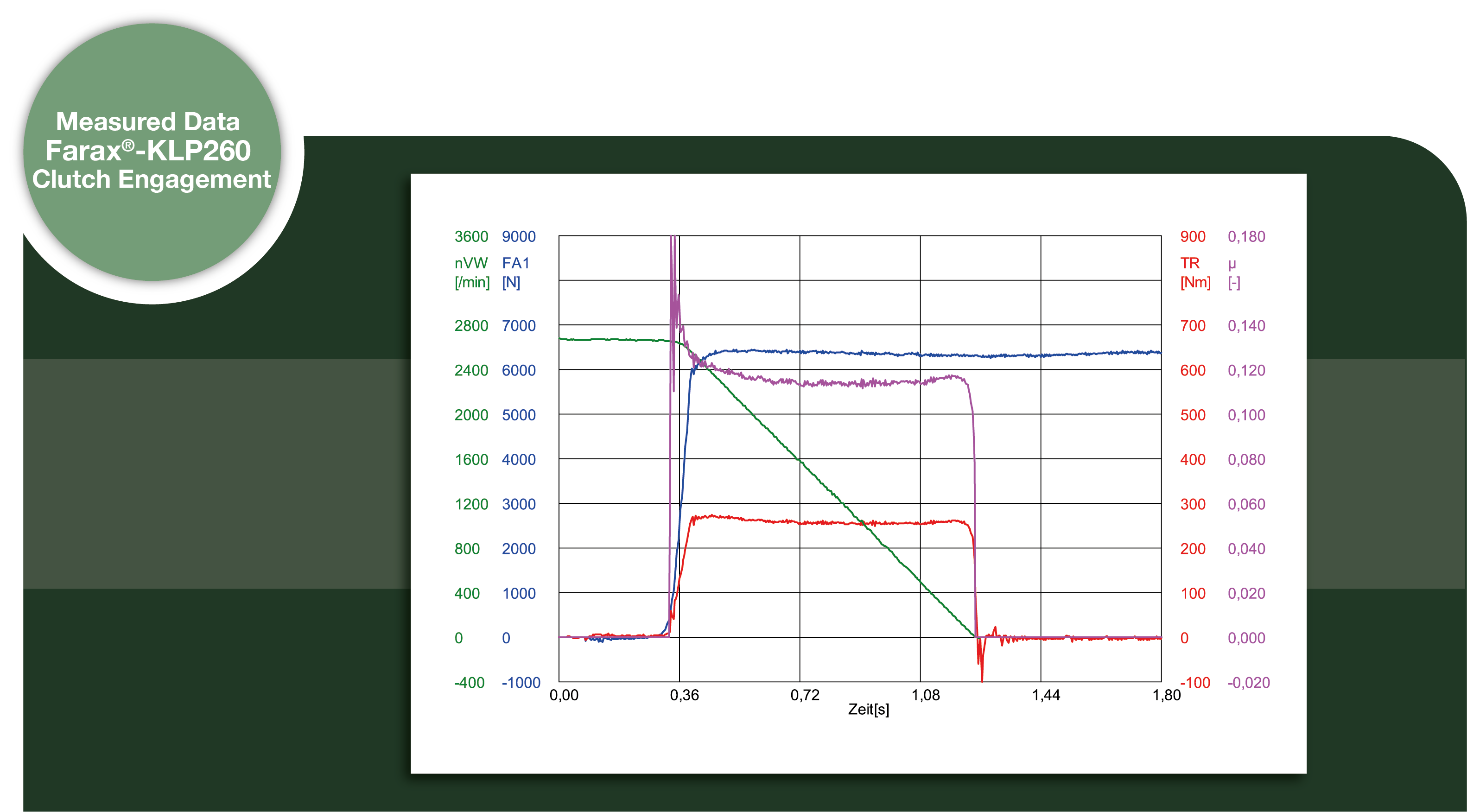

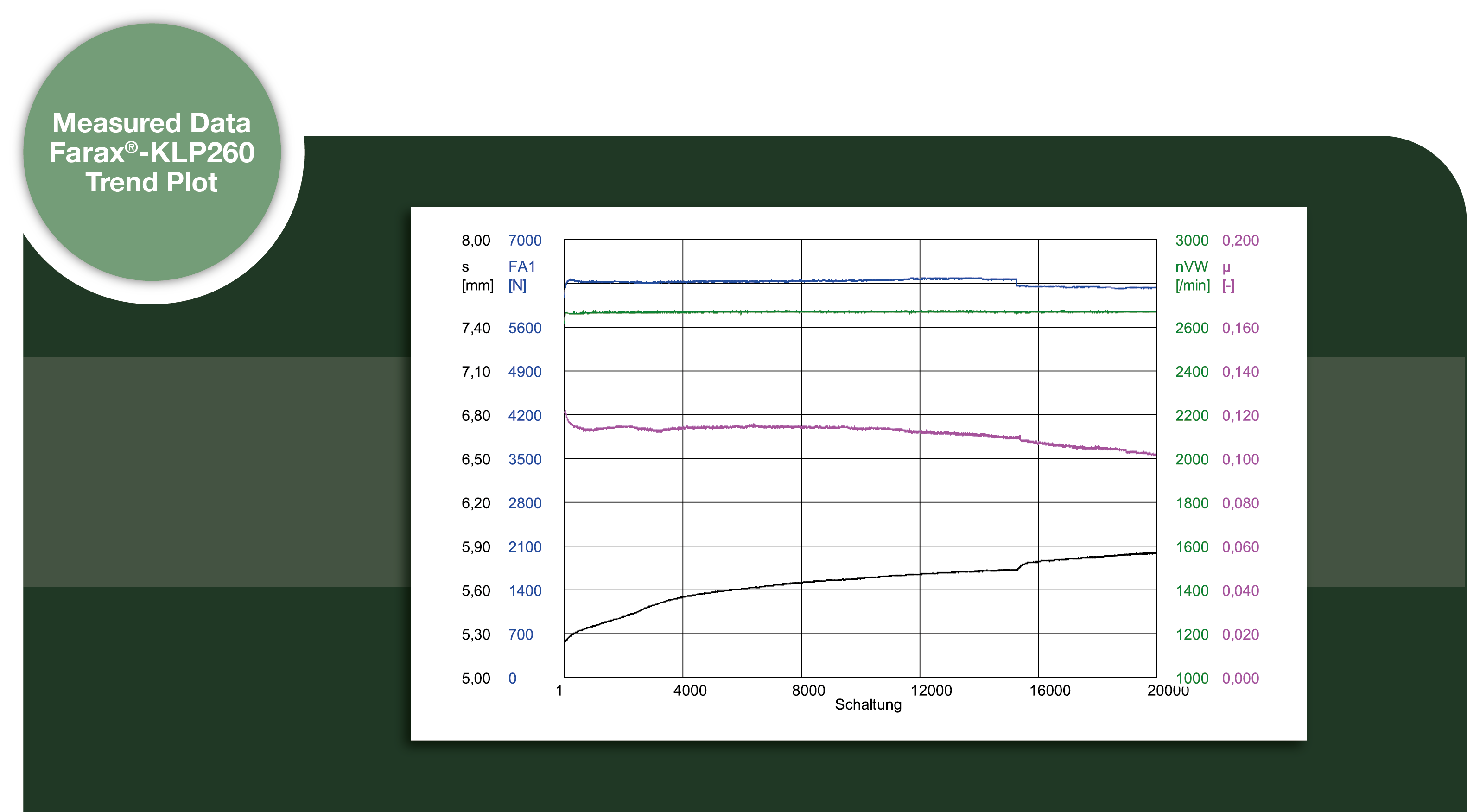

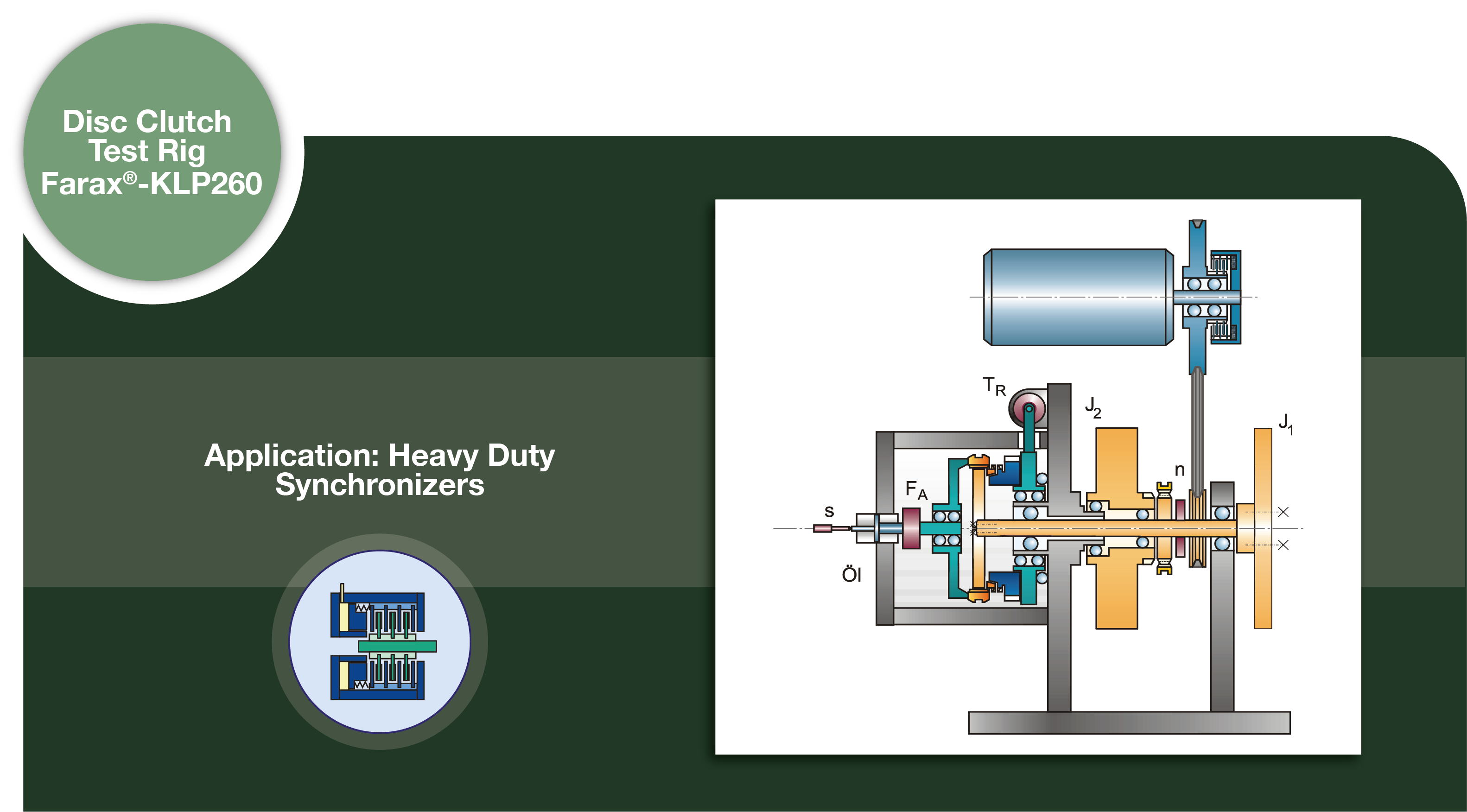

The ZF/FZG KLP 260 test bench is a brake test bench with an outer carrier fixed to the housing, as well as a rotating inner carrier. With this test rig, a complete clutch of the transmission is installed. The load is applied to the outer plates, at which the friction torque of the clutch is also measured. The clutch is cooled from the inside with defined cooling oil flow. The test rig is also supplied with an extra lubrication unit with controlled oil circulation (heating and cooling).

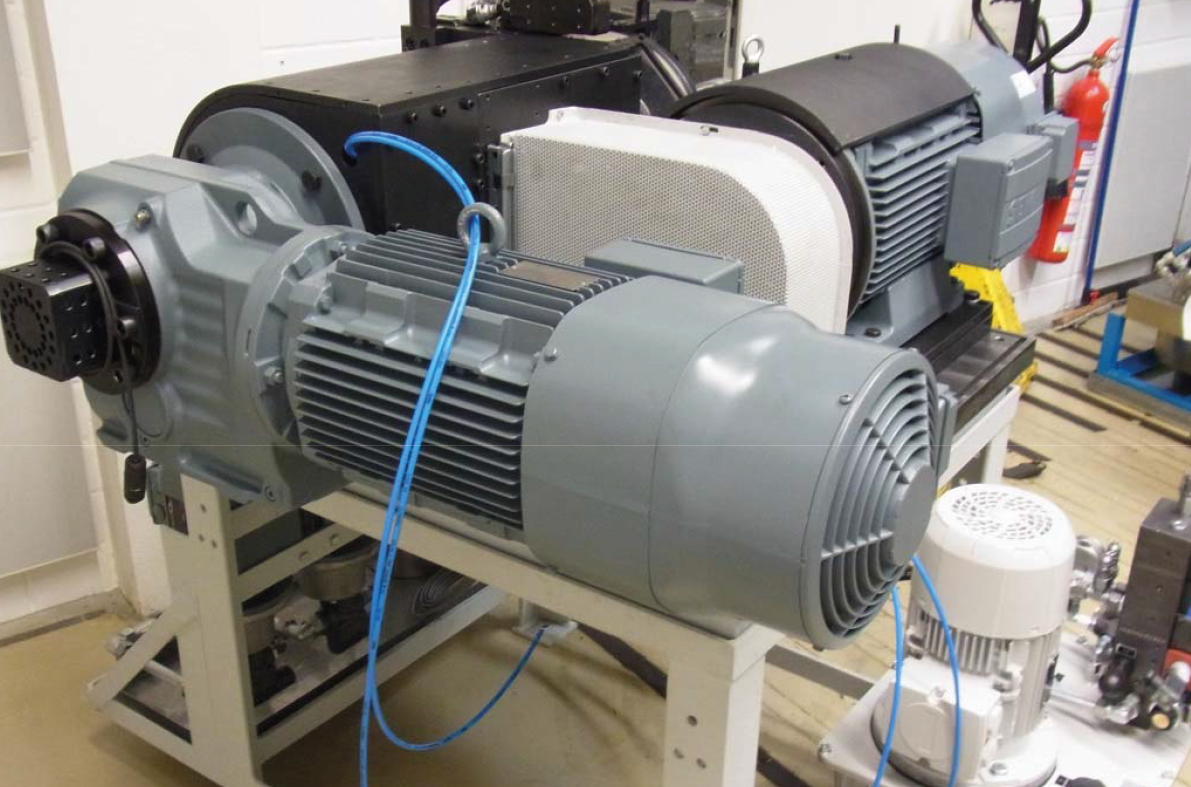

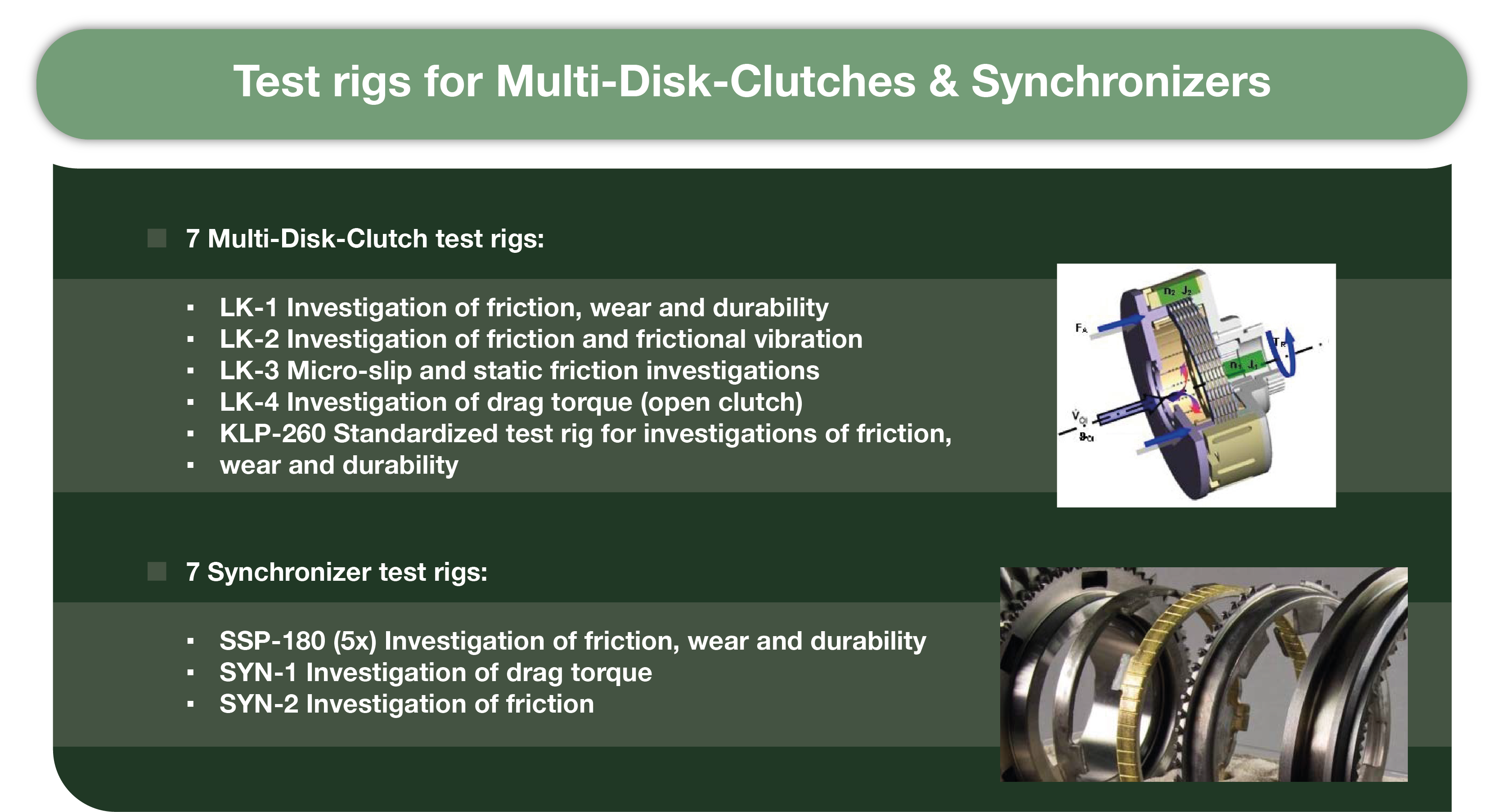

7 Multi-Disk-Clutch test rigs:

• LK-1 Investigation of friction, wear and durability

• LK-2 Investigation of friction and frictional vibration

• LK-3 Micro-slip and static friction investigations

• LK-4 Investigation of drag torque (open clutch)

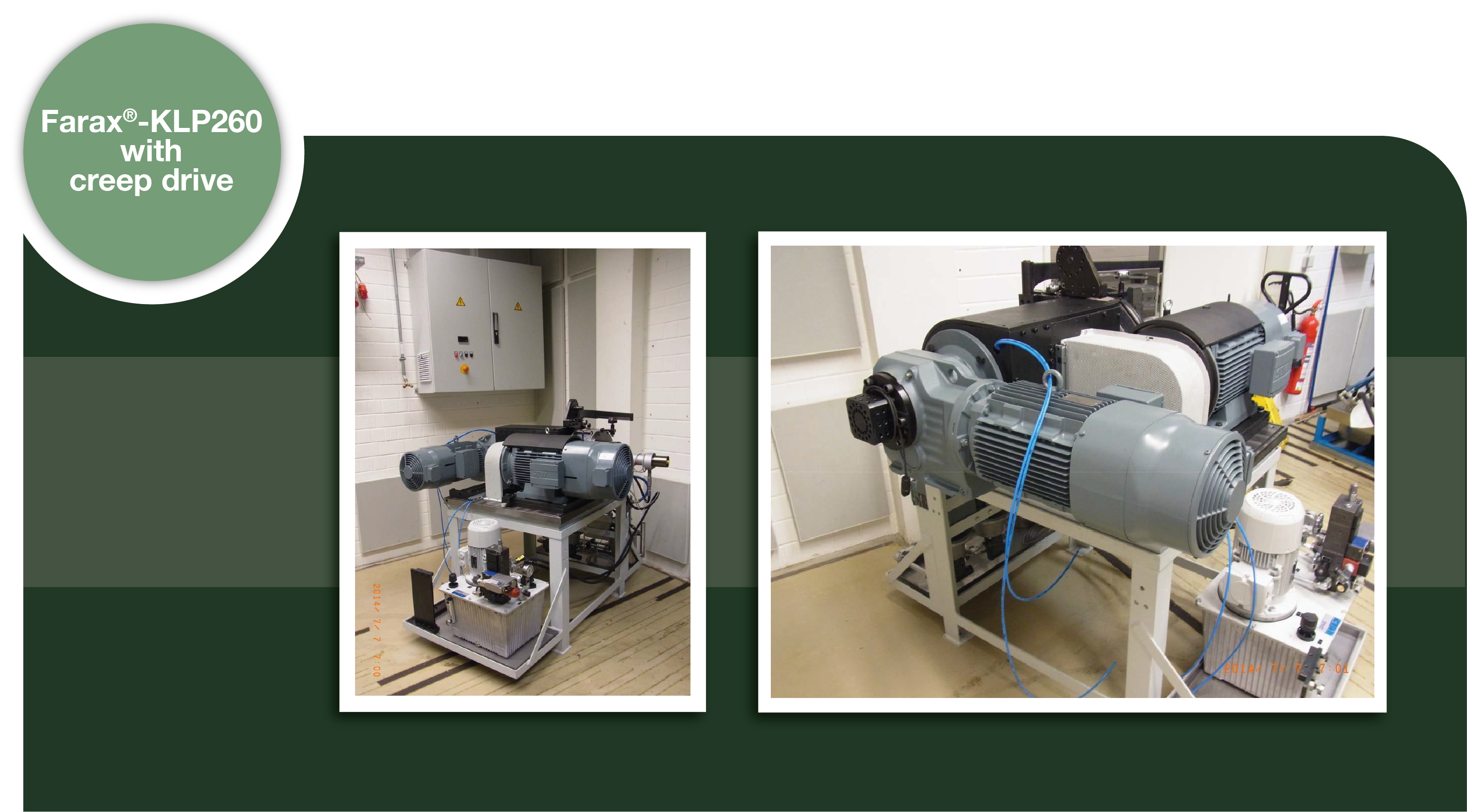

• KLP-260 Standardized test rig for investigations of friction, wear and durability

7 Synchronizer test rigs:

• SSP-180 (5x) Investigation of friction, wear and durability

• SYN-1 Investigation of drag torque

• SYN-2 Investigation of friction

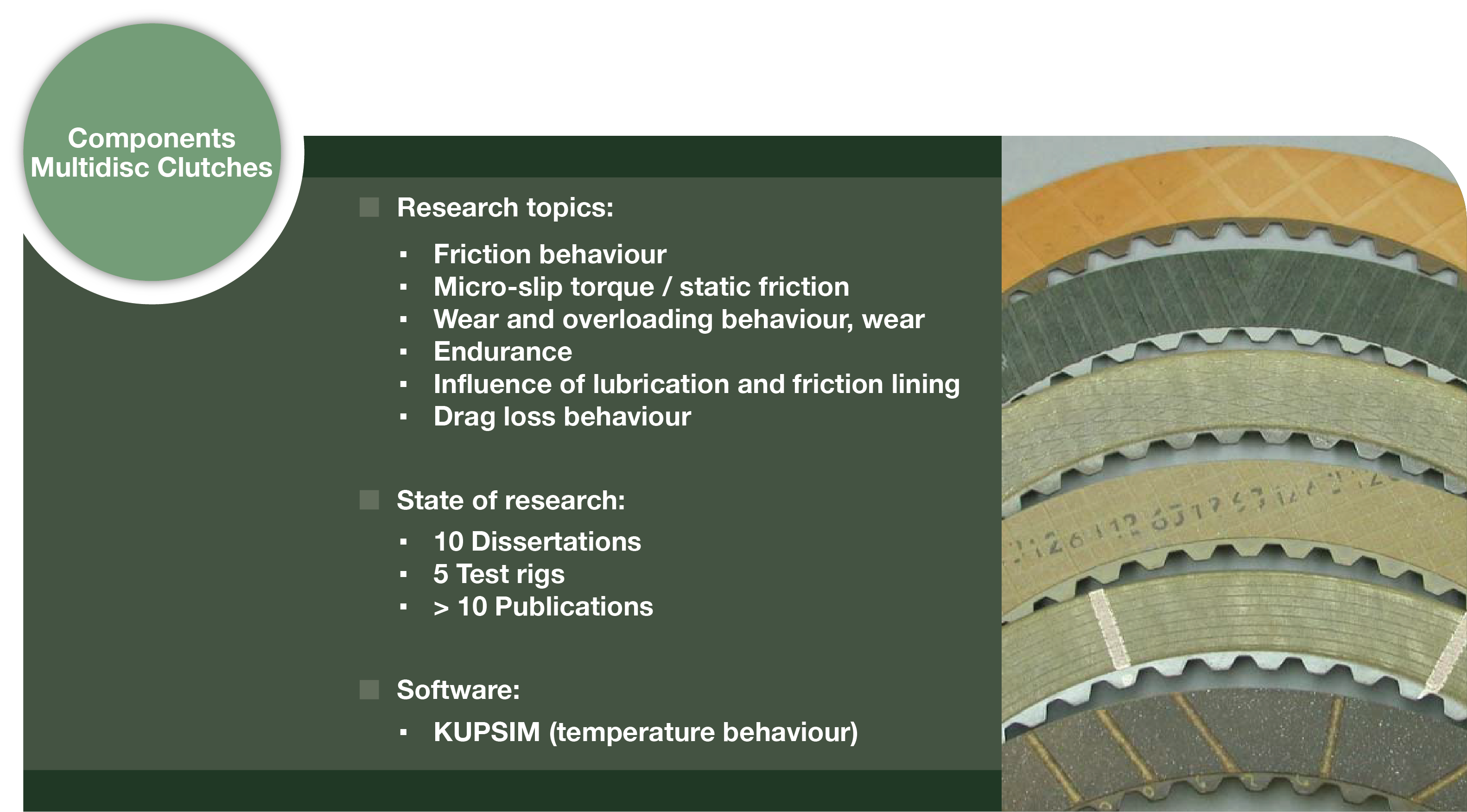

Research topics:Friction behaviour

• Micro-slip torque / static friction

• Wear and overloading behaviour, wear

• Endurance

• Influence of lubrication and friction lining

• Drag loss behaviour

State of research:

• 10 Dissertations

• 5 Test rigs

• > 10 Publications

Software:

• KUPSIM (temperature behaviour)

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany