- Contact Us

- phone: +49 (0) 931 32298-0

- mail: info@innowep.com

- Friedrich-Bergius-Ring, 11

- 97076 | Würzburg | Germany

Material & surface profilometry is the study and analysis of the physical characteristics of a material or surface. It is used to measure the surface roughness, texture, and other characteristics of a material or surface in order to assess its suitability for a given application. This type of analysis is important for product development, quality control, and other areas of manufacturing and engineering. In addition to measuring surface roughness, texture, and other properties, profilometry may also be used to measure the thickness, density, and other physical properties of a material or surface.

Tactile and optical measurements with micro- and nanometer resolution are typically used to measure the size and shape of extremely small objects. Tactile measurements involve the physical contact of a probe with the object, while optical measurements rely on light to capture an image of the object.

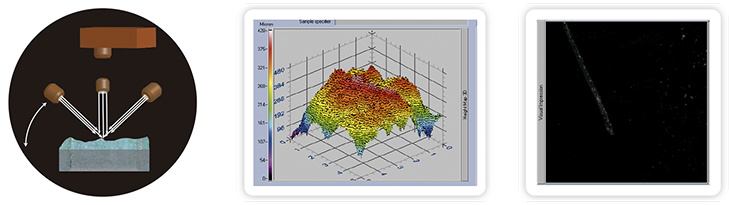

Tactile measurements are best for measuring surface features or shapes, such as roundness, flatness, concentricity, or surface roughness. Common techniques include scanning probe microscopy, atomic force microscopy, and stylus profilometry. These techniques use a probe that is maneuvered over the surface of the object to measure its features.

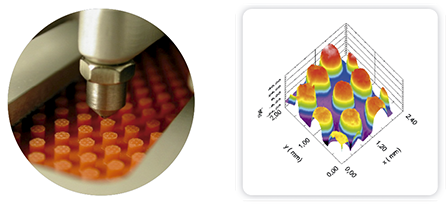

Optical measurements are best for measuring the size and shape of objects that are too small to be measured by tactile methods. Common techniques include interference microscopy, confocal microscopy, and optical profilometry. These techniques use light to capture an image of the object, which can then be processed to measure its size and shape.

• Roughness

• 3D Topography/Mapping

• Macro & micro geometries

• Light intensity

• Porosity

• Effective contact area ratio

The following technical equipment can be used for topography characterizations:

• UST®-Universal Surface Tester

• Traceit®

• White-light interferometer with height measurement range of 100 µm (surface

roughness characteristics according to DIN EN ISO 25178)

• Confocal laser scanner (SurfScan)

• Tactile roughness measuring instrument (profilometer, roughness parameters

according to DIN EN ISO 4287)

• Atomic force microscope (AFM)

Questions?

We are happy to help!

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany