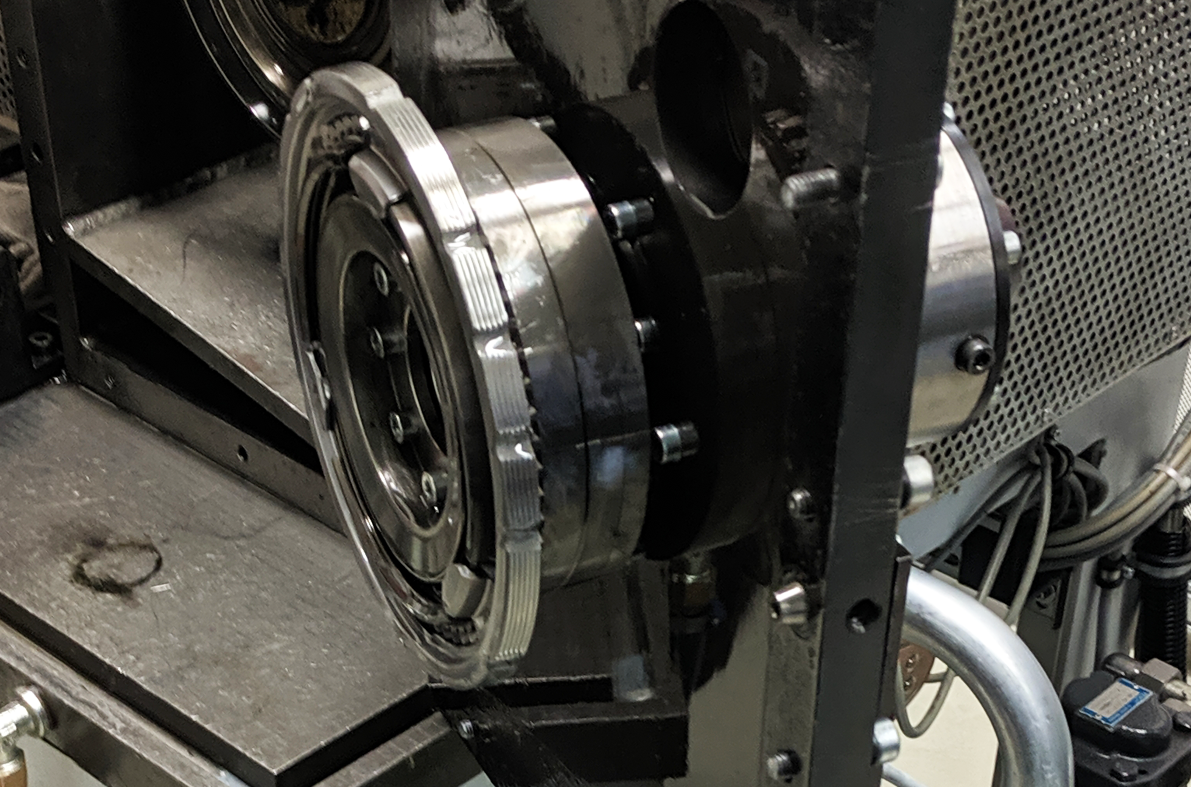

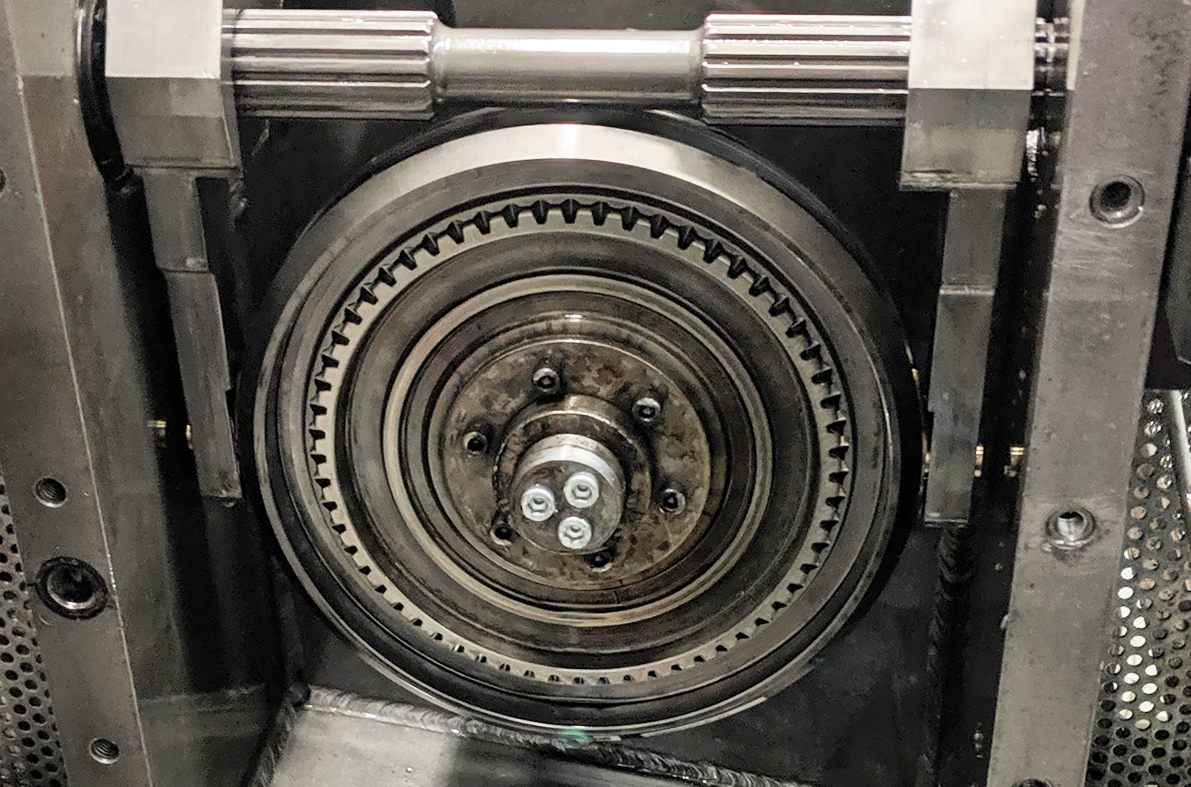

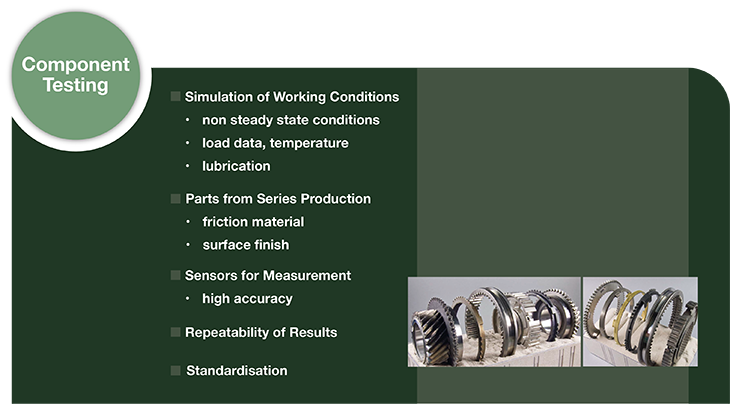

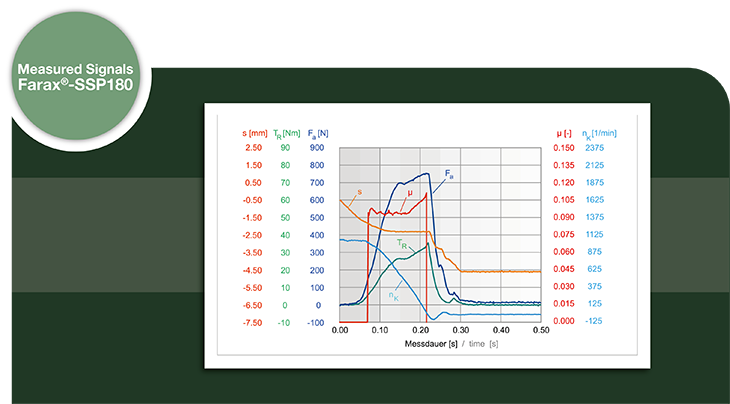

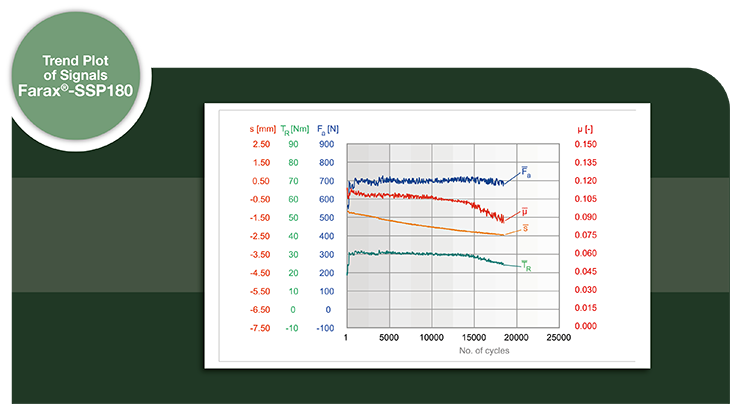

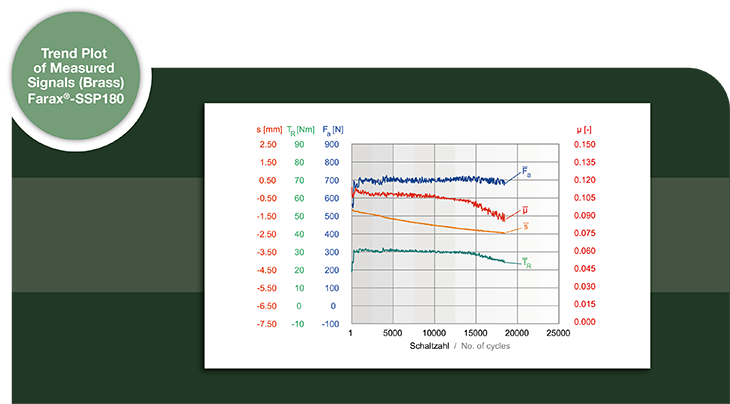

Synchronizer rings are evaluated on a FARAX-ZF/FZG-SSP180 synchro test-rig for the study of the tribological properties and wear behavior.

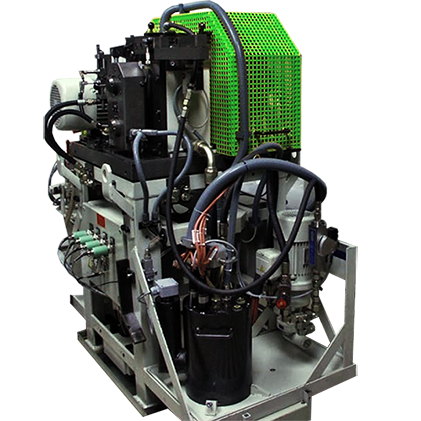

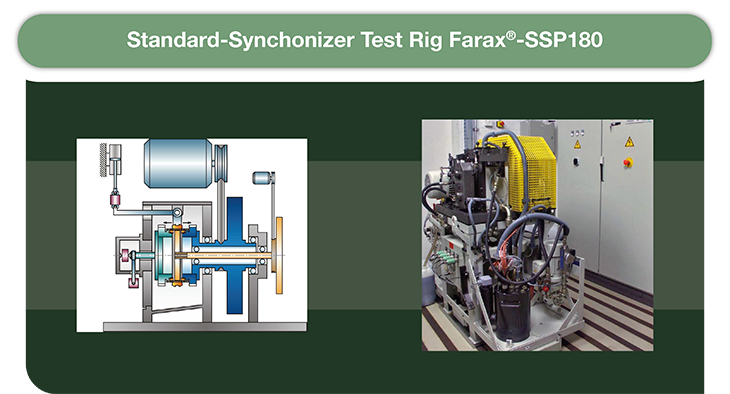

A standard synchronizer-test-rig FARAX-ZF/FGZ-SSP180 was developed by the Gear Research Center (FZG) of the Technical University of Munich, is now under the product line at Innowep labeled as FARAX-ZF/FGZ-SSP180.

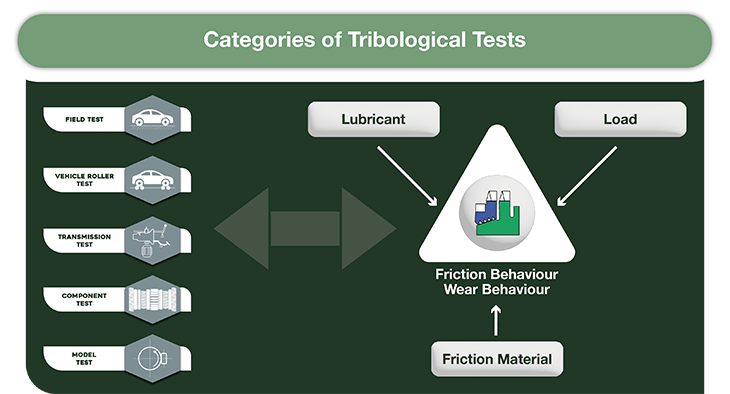

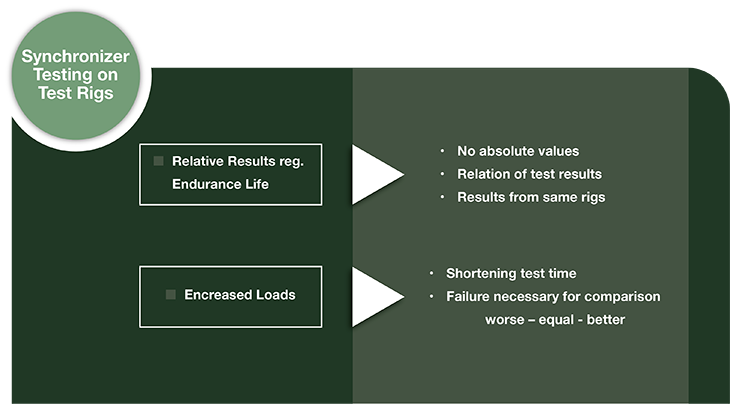

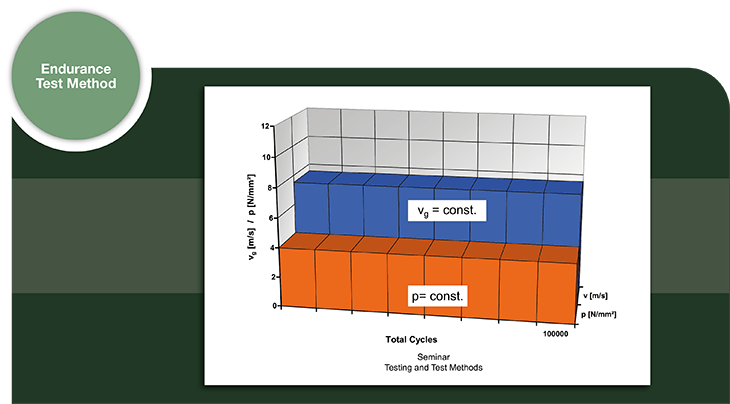

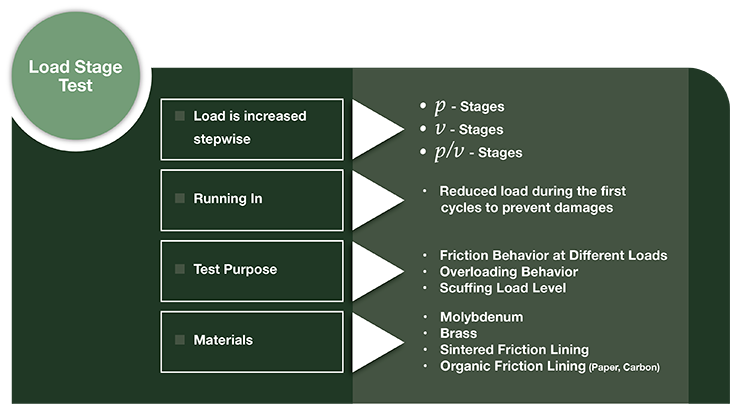

It is a well established test rig and test method to evaluate friction and wear properties of friction materials in synchro-systems under varying loads.

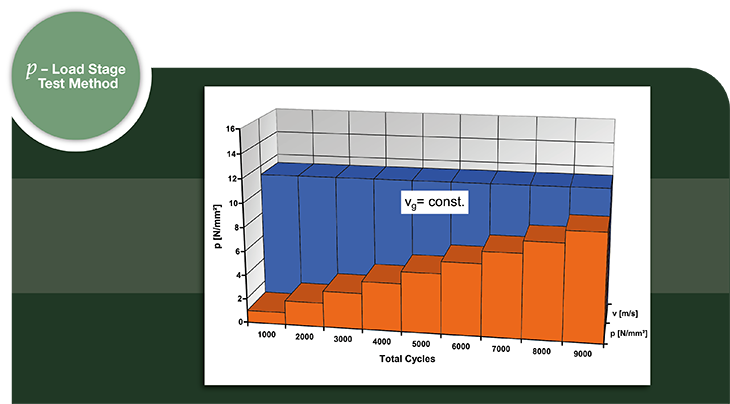

Normal test procedure involves first a quick evaluation of the friction behavior under varying loads the "p-n load-step”.

• 1,000 cycles at each load step;

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany