Importance of Durability Tests on Displays and Touchscreens

Over the decades, the touch design has been changing from the simple button/knob to a display, either non-interactive or interactive touchscreen.

Since 2012, OEMs in various industries have started to integrate touchscreens into their products.

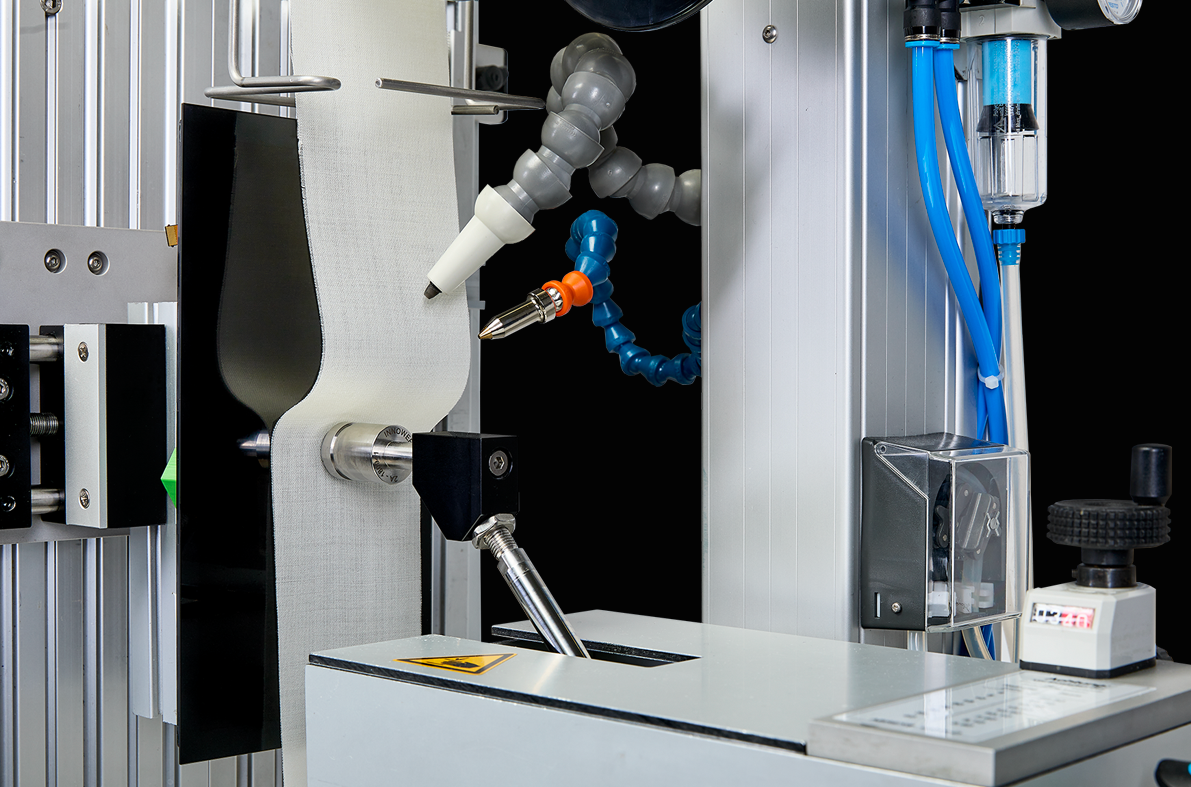

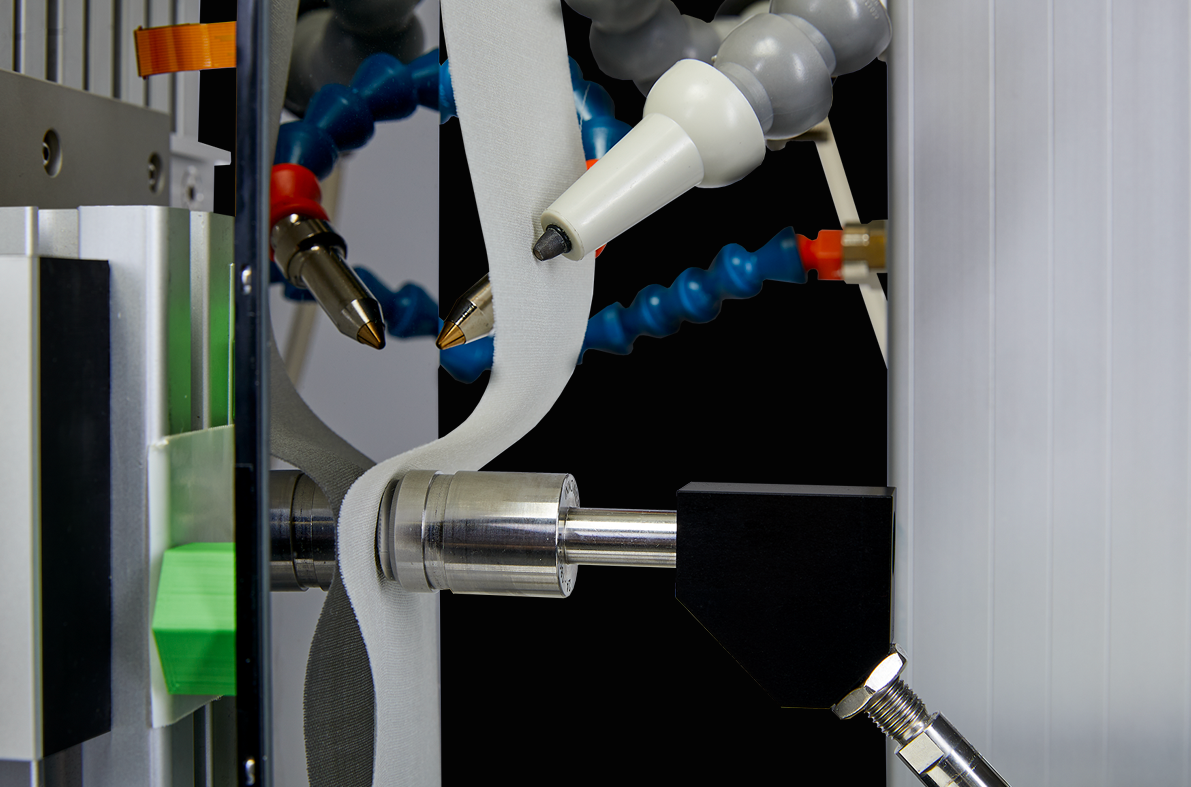

ABREX®-D is designed for display durability testing and it is so far the only testing machine that fulfills VDE SPEC 90017 and many display specifications.

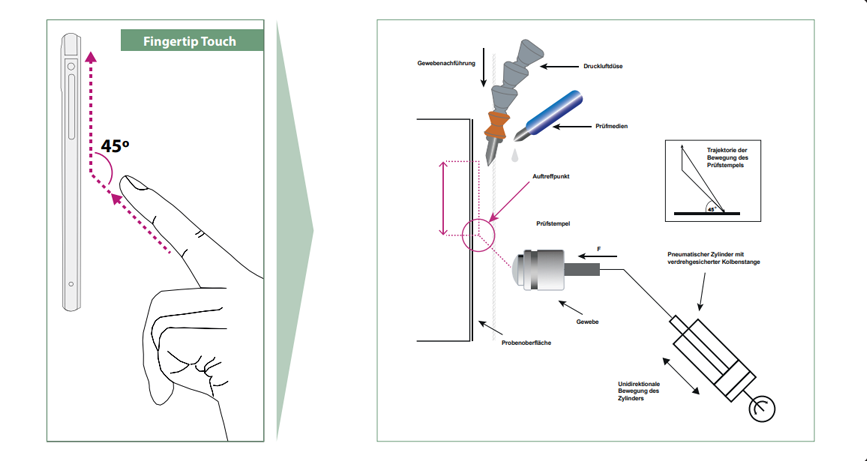

ABREX®-ABRASION, is a soft-chemo-mechanical fingertip & hand abrasion. The simulated wear pattern matches reality with 99% accuracy. It is a highly complex abrasion process which involves:

• A 45° angle impact driven by a dynamic pneumatic cylinder attached with a viscoelastic fingertip under a defined load;

• Then a friction rubbing or tumbling motion between the sample and a textile containing dirt, dandruff, oil, sweat or various types of testing liquids;

• Followed by a retraction movement with or without the contact at the surface depending on the application.

| standard ABREX® | ABREX®-E | ABREX®-A | ABREX®-D | ABREX®-C | ABREX®-CE | |

| Load | 1-20N | |||||

| Friction Path | 4-40 mm | |||||

| Standard Cyclic Speed Abrasion, cleanability tests) | 6 ± 0.5 cm/s | 6 ± 0.5 cm/s (S mode); 20 cm/s (D mode | 6 ± 0.5 cm/s | |||

| Scratch Speed (single stroke) | N/A | 20 ± 2cm/s & 70 ± 5 cm/s acc. to GS97034-2 for fingernail test 70 ± 5 cm/s acc. to GS 97034-3 for shoe sole test. | N/A* | N/A | 6 ± 0.5 cm/s | 20 ± 2cm/s & 70 ± 5 cm/s acc. to GS97034-2 for fingernail test 70 ± 5 cm/s acc. to GS 97034-3 for shoe sole test. |

| Cycles | 1-10,000,000 | |||||

| Piston | 20mm Standard 10mm Standard | 20mm Standard 10mm Standard | 20mm Standard 10mm Standard | 20mm Standard 10mm Standard | both 10mm & 20mm for 3 temperature range: -40-0o C | 0-30o C and 30-85o C | both 10mm & 20mm for 3 temperature range: -40-0o C | 0-30o C and 30-85o C |

| Liquid | Automatic | Manual | |||||

| Fabric | Automatic | Feed Adjustable | |||||

| Electricity | 230V / 50Hz; 110V / 60Hz | |||||

| Compressed Air | 4 bar, external, oil free, water free | |||||

• Visible defects

Scratches can be easily made under the dynamic motion of human beings. Fingerprint or dirt print affinity is another issue; either easily removed by a few cleaning steps or certain anti-fingerprint coatings are applied to prevent those imprints.

• Non-visible defects

Abrasion is often caused by human finger touch/ swipe/ zoom actions and other mechanical loads. Under this abrasion, the layers of functional coatings can suffer invisible damages and these micro defects, will result in a malfunction of the display. The natural behavior of a customer who identifies a problem with the functioning of a touchscreen is to return the entire product, causing an undesirable cost to the producer.

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany