Purpose of the Device

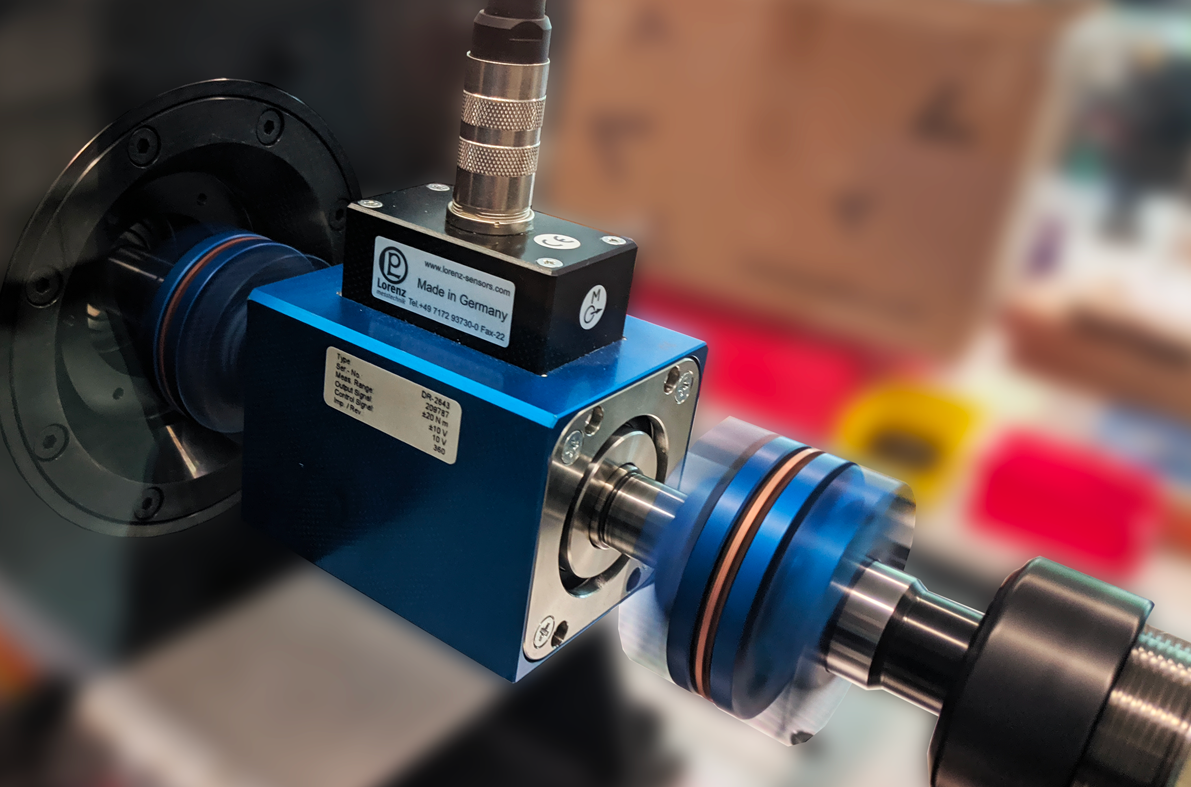

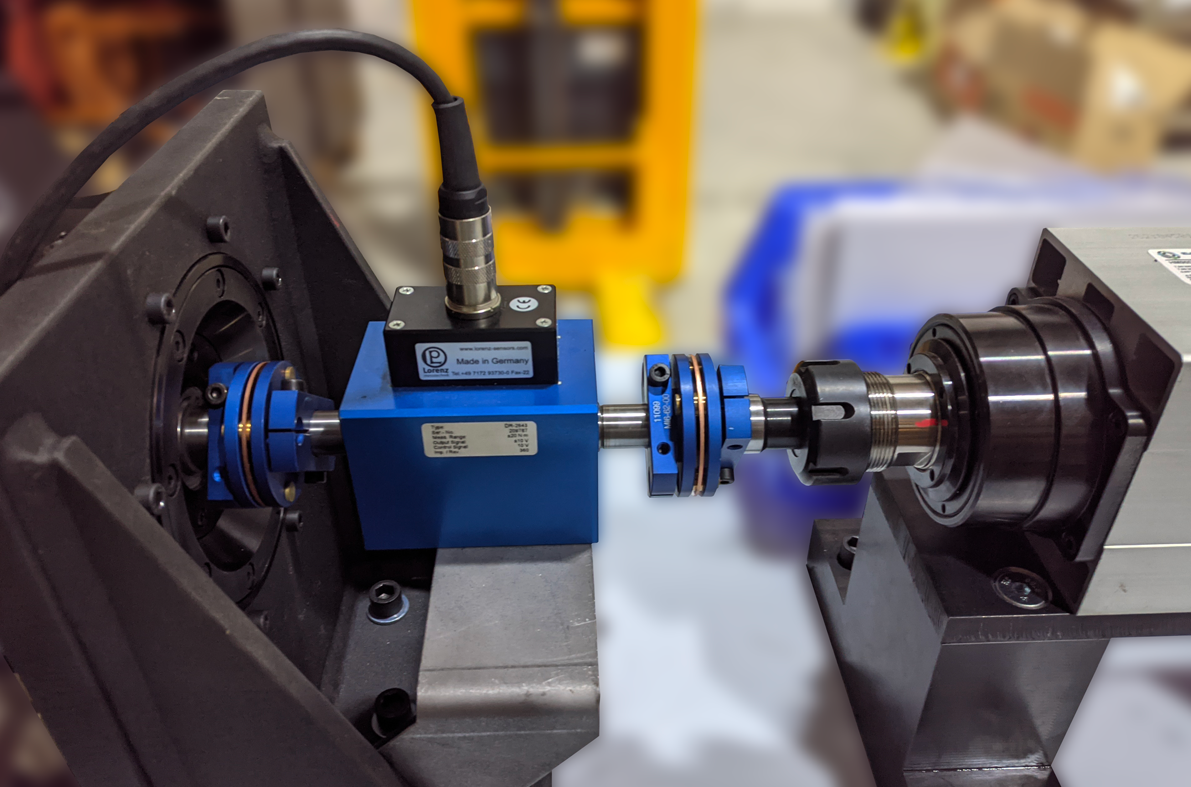

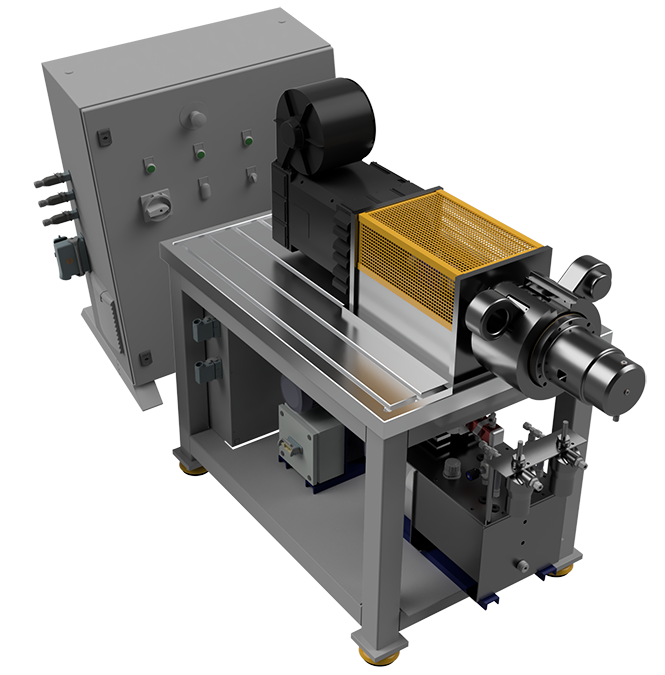

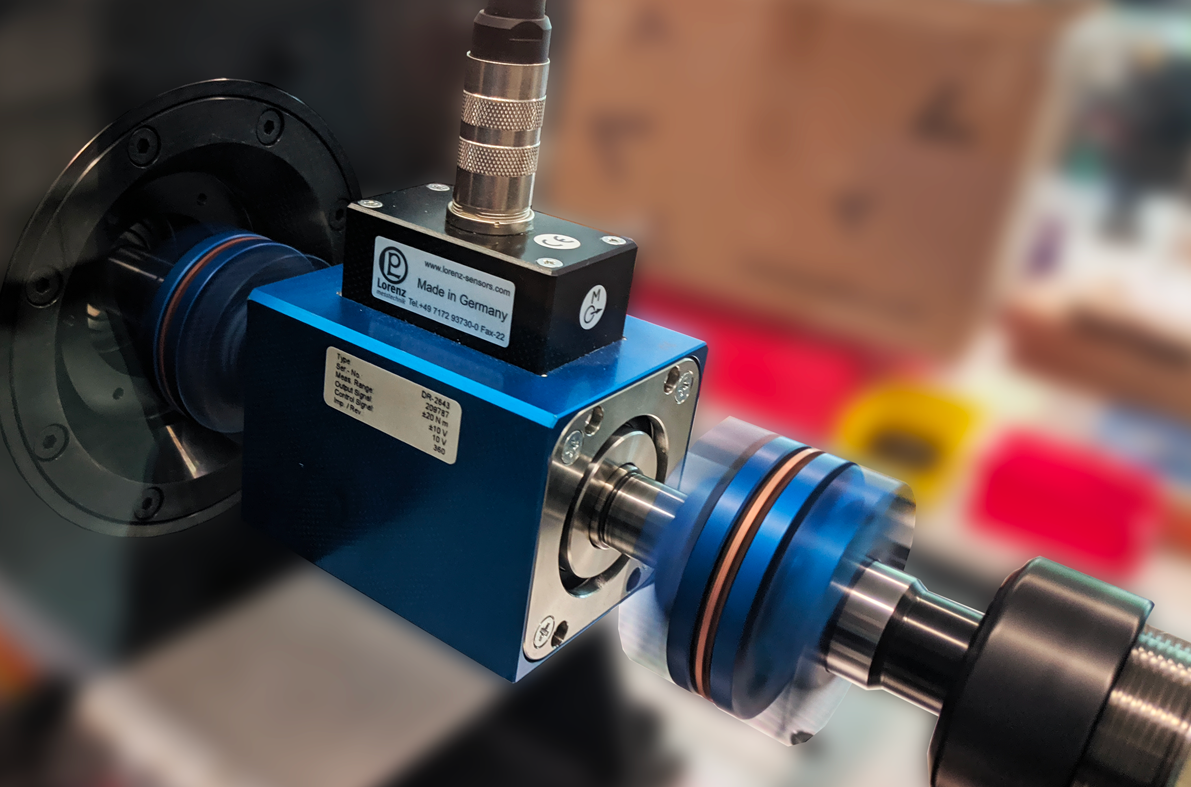

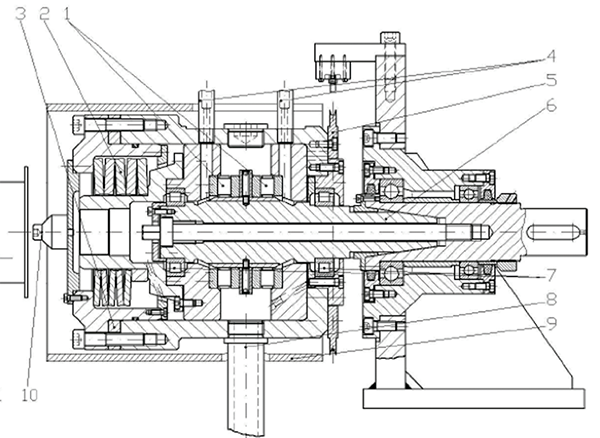

The FE8 test rig is used to examine lubricating oils and greases with regard to their wear and friction behaviour under lubricant and bearing-specific influences according to DIN51819 standard and VW, ZF, Mercedes methods. Innowep supplies customized and advanced FE8 which applies hydraulic loading with variable load and speed controls.

• Meet DIN 51819 Standard

• Speed 7.5-4,500rpm

• Load 100KN

• Standard Spring Loaded

• Standard FAG Test Bearings

• Single-station Test Bench, Multi-station

| FARAX®-BEARING-FE8-H | |

| Drive - Servo Drive | |

| Drive speed | nmax 5800min-1 |

| Km 1.4Nm/A | |

| KE(eff) 86.3V/1000min-1 | |

| U(max) AC 600V | |

| Natural convection | Md0 60k 32Nm |

| Id0 60k(eff) 25.1A | |

| IP65 | |

| Weight | m 28.3kg |

| Drive - Gear | |

| Power rating | PB 19KW |

| Nominal driving speed | nB 1500min-1 |

| Maximal input torque | MB 120Nm |

| Max input driving speed | nmax 12000min-1 |

| Gear ratio | i 4.91 |

| Maximal output torque | Mmax 589Nm |

| Weight | ca.30Kg |

| Operating Temperature | 0…200°C/32…392°F |

| Operating Speed | with i=1:17.5…3000rpm |

| Operating Speed | with i=1:4,917.5…610rpm |

| Maximal Test Force | 100kN |

| Maximal Friction Torque | 50Nm |

| Minimal Tank Volume | 3litres |

| Minimal Tank Volume | for heating with tubular heating element3.5litres |

| Recommended Viscosity | (gear pump of lubrication system)20…100mm²/s |

| Heating Band | 1000W |

| Fan of Heating Cooling Cover | 400W |

| Fan of Heating Cooling Cover | (one of the two fans)32W |

| Tubular Heating Element of Lubrication System | 500W |

Special Test Bearings

• Angular contact ball bearings with brass cage Brass Cage Angular Contact Ball Bearings

• Taper roller bearings with cage of sheet metal Sheet Metal Cage Tapered Roller Bearings

• Axial cylindrical roller bearings with brass cage Brass Cage Thrust Cylindrical Roller Bearing

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany